Timing relays are a type of relay that delays the switching action for a fixed or adjustable amount of time after a change in the control signal. This allows a sequence of operations in a control circuit to be automatically started and stopped at different time intervals, eliminating the need for manual control.

Timing relays are used in a wide variety of applications, such as:

- Controlling the start and stop times of motors, pumps, and other equipment

- Creating timed delays for alarms, security systems, and other safety devices

- Sequencing the operation of multiple devices in a manufacturing process

- Providing timed delays for irrigation systems and other outdoor applications

Motor-Driven Timers

Timer functions are responsible for timing a cycle of operation, delaying the starting or stopping of an operation, and controlling time intervals within an operation. Motor-driven timers are employed to time a cycle of operations.

Synchronous clock types utilize a small electric clock motor driven from the AC power line to maintain sync with standard time. A mechanical connection to the clock mechanism controls the contacts. The operation of the device can be summarized as follows:

- The motor turns the mechanism and actuates normally open or normally closed contacts.

- Adjustable on/off tabs set along the clock’s timing wheel trip the contact open or closed.

- The timer motor is supplied with continuous power. If power is lost, the timing will be delayed by an amount of time the power was off, and the correct time must be manually reset.

- These types of timers are best suited for applications such as lighting and water sprinkler control where precise timing is not critical.

Dashpot Timers

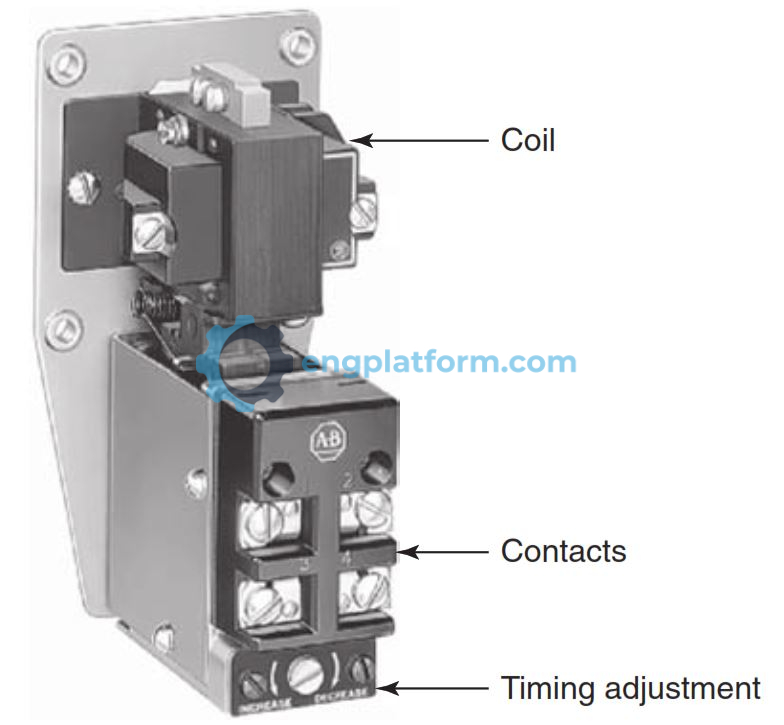

Dashpot timers use a fluid or air to delay the switching action for a set amount of time. Pneumatic timing relays use an air bellows system to achieve the timing cycle. When the coil is energized or de-energized, air enters the bellows through an orifice at a predetermined rate. The rate of airflow determines the length of the time delay. Smaller orifice openings result in longer time delays. Pneumatic timers have a relatively small adjustable range. The timer shown has a timing range of 0.05 to 180 seconds with an accuracy of approximately +10%.

Solid-State Timing Relays

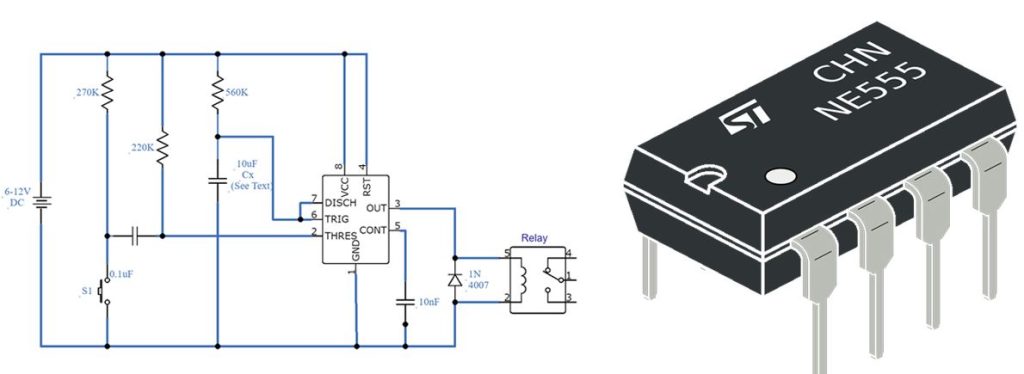

Solid-state timing relays use electronic circuitry to delay the switching action for a set amount of time. They are much more accurate than dashpot timers and can control timing functions ranging from a fraction of a second to hundreds of hours.

Solid-state timers can be divided into two broad categories: analog and digital.

- Analog solid-state timers use a resistor/capacitor (RC) charge and discharge circuit to obtain the time base.

- Digital solid-state timers use a quartz clock as the time base.

Solid-state timers are normally constantly powered in order to maintain their timing operations. Some are equipped with batteries or internal memory to retain their settings during power failures.

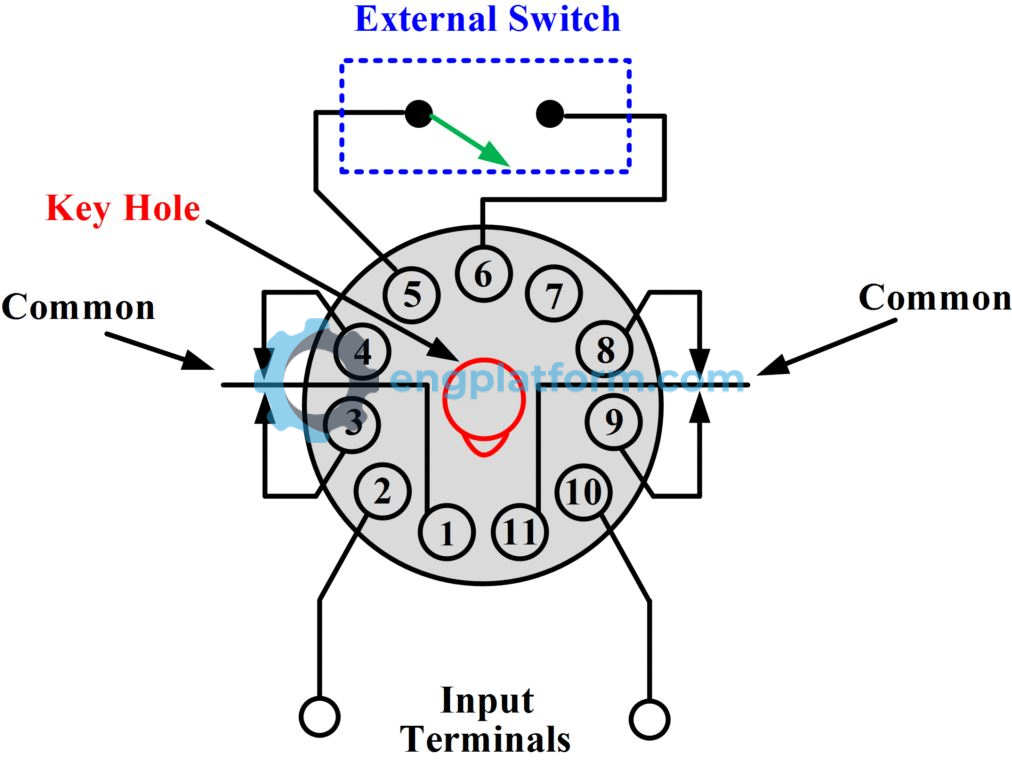

The timing functions of dashpot timers are initiated when the electromagnetic coil is energized or deenergized. In comparison, solid-state timing functions are initiated when the electronic circuit of the timer is energized or a triggering signal is received or removed. Electronic timers are available in a variety of rated input operating voltages.The operation of the device can be summarized as follows:

- Connections provided include timed contacts (C1, C2), voltage input (L1, L2), and external trigger switch (S1, S2).

- A timing-delay period of from 0.1 to 2 seconds is set by the adjustment of an internal potentiometer located on the front panel of the timer.

- The timer is energized continuously, and timing is initiated when the external trigger circuit is closed.

- The timed contact is convertible to on-delay or off-delay.

Timing Functions

There are four basic timing functions: on-delay, off-delay, one-shot, and recycle.

ON-DELAY TIMER

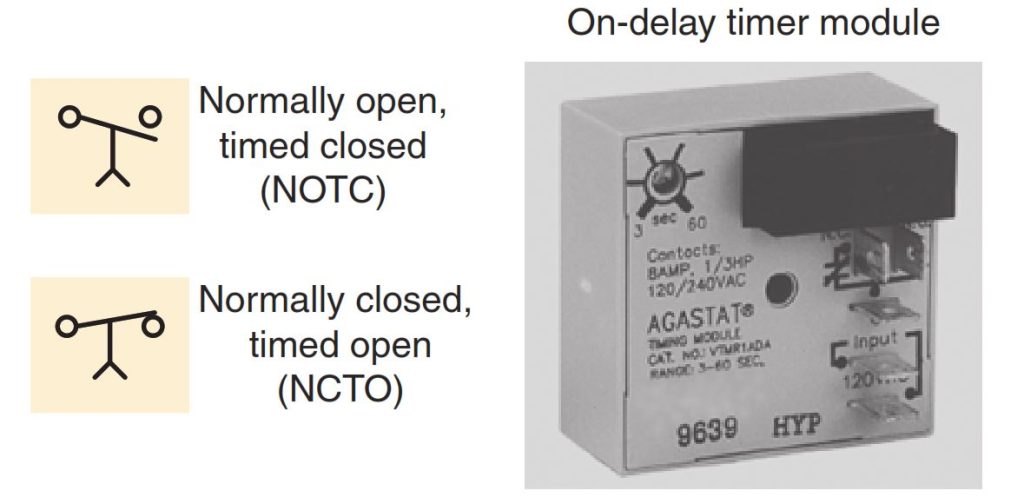

The on-delay timer is sometimes referred to as DOE, which stands for delay on energize. The time delay of the contacts begins once the timer is switched on; hence the term on-delay timing. The operation of the timed contacts can be summarized as follows:

- Once initiated, DOE timed contacts change state after a set time period has passed.

- After that time has passed, all normally open timed contacts close and all normally closed contacts open.

- Once the timed contacts change state, they will remain in this position until the power is removed from the coil or electronic circuit.

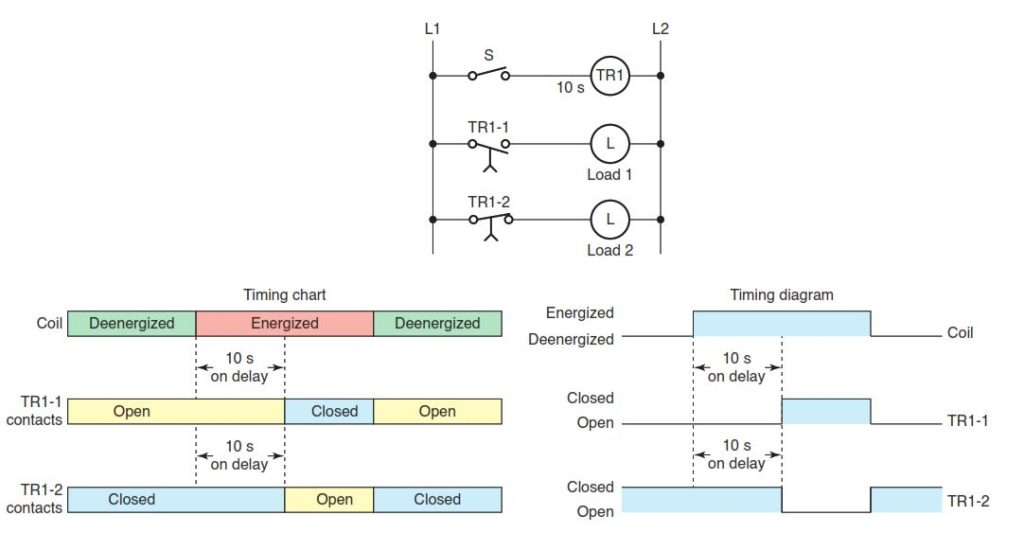

The circuit shown in figure below illustrates the tim-ing function of an on-delay timing relay. In this exam-ple, a simple dashpot timer with a time delay setting of 10 seconds can be assumed. The same operation applies to electronic timers that perform a similar function. The operation of the circuit can be summarized as follows:

- When the switch is closed, power is applied to the coil but the contacts are delayed from changing position.

- With the switch still closed, after the 10-second timing period the normally open contacts (TR1-1) close to energize load 1 and the normally closed contacts (TR1-2) open to de-energize load 2.

- If the switch is then opened, the coil deenergizes immediately, returning both timed contacts to their normal state, switching load 1 on and load 2 off.

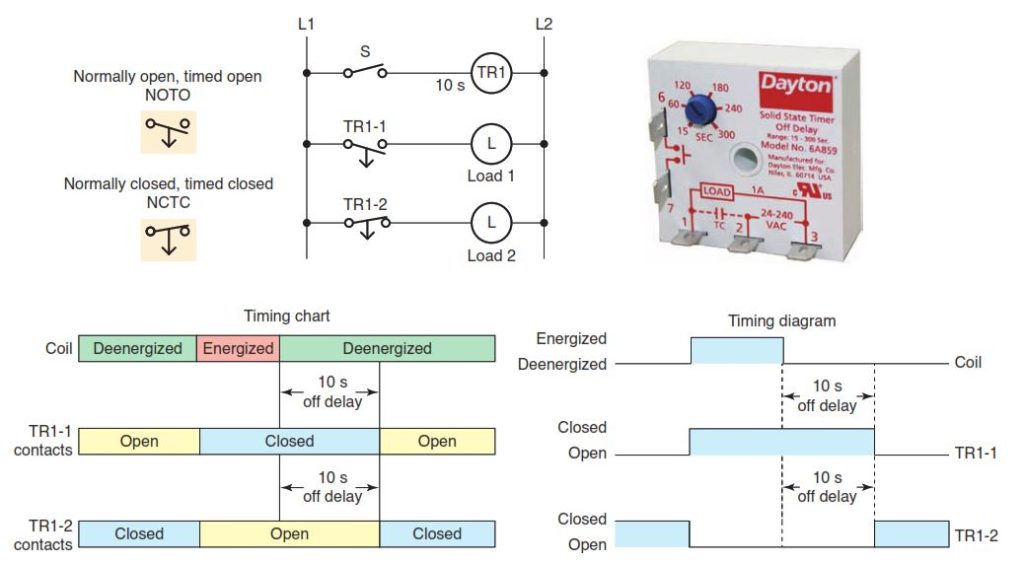

OFF-DELAY TIMER

The off-delay timer is sometimes referred to as DODE, which stands for delay on de-energize. The operation of the off-delay timer is the exact opposite of that of the on-delay timer. When power is applied to the coil or electronic circuit, the timed contacts will change state immediately. When power is removed, however, there is a time delay before the timed contacts change to their normal deenergized positions.

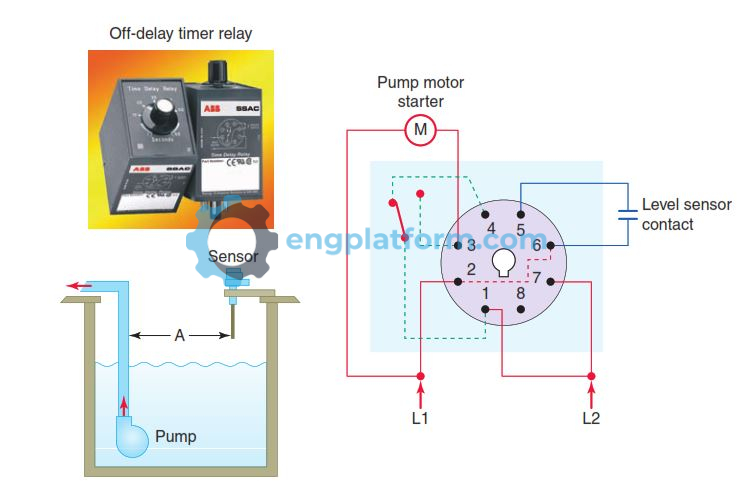

Figure below shows the wiring diagram for the automatic pumping down of a sump using a level sensor switch and plug-in cube-type off-delay timer. A solid-state timing circuit drives an internal electromechanical relay within the timer. The operation of the circuit can be summarized as follows:

- When the level rises to point A, the level sensor contact closes to energize the relay timer coil and close the NO contacts to the pump motor starter.

- This immediately turns the pump on to initiate the pumping action.

- When the height of the vessel level decreases, the sensor contacts open and timing begins.

- The pump continues to run and empty the tank for the length of the time-delay period.

- At time-out the relay coil deenergizes and the normally open relay contact reopens, turning the pump off.

- The timer has a built-in time adjustment potentiometer that is adjusted to empty the tank to a desired level before the pump shuts off.

ONE-SHOT TIMER

With a one-shot timer, momentary or continuous closure of the initiate circuit results in a single timed pulse being delivered to the output. The one-shot causes this action to happen only once, and then must be reinitiated if it is to continue to operate. The circuit of Figure below illustrates the wiring and timing function of a typical one-shot timer. The operation of the circuit can be summarized as follows:

- Input voltage must be applied before and during timing.

- Upon momentary or maintained closure of the initiate button, the output load is energized.

- The load remains energized for the duration of the time-delay period and then is return to its normal deenergized state ready to be initiated for another cycle of operation.

- Opening or reclosing the initiate button during timing has no effect on the time delay. Reset occurs when the time delay is complete and the initiate button is open.

- If power is interrupted to a one-shot timer during the time-delay operation, the time delay is canceled. When power is restored to the timer, the time-delay function will not begin again until the one-shot has been reinitiated.

- One-shot timers do not have dedicated contact symbols. Instead, the standard NO and NC contact symbols are used and referenced to the timer that controls them.

RECYCLE TIMER

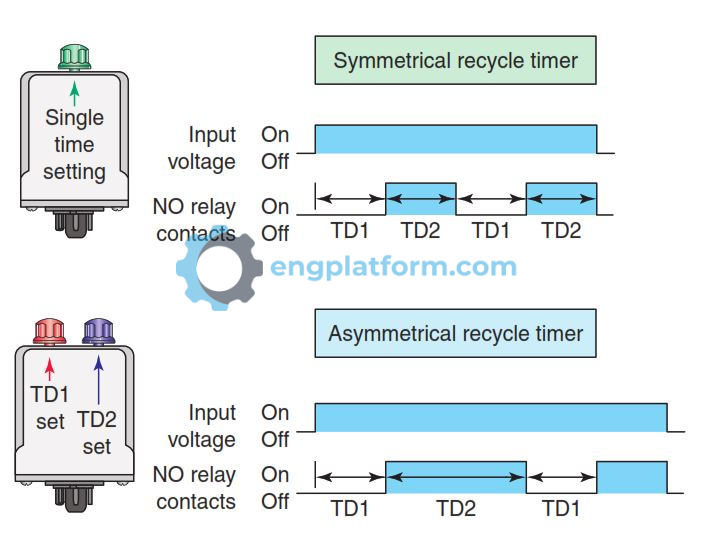

The contacts of a recycle timer alternate between the on and off states when the timer is initiated. Solid-state circuits within the device drive an internal electromagnetic relay. The operation of the recycle timers shown in figure below can be summarized as follows:

- Upon application of input voltage, the first delay period (TD1) begins and the output remains deenergized, or off.

- At the end of the first delay, or off period, the relay coil will energize and the second delay (TD2), or on period, begins.

- When the second delay period ends, the relay deenergizes.

- This recycling sequence will continue until input voltage is removed.

- In some recycling timers, the on time may be configured for the first delay. Removing input voltage resets the output and time delays, and returns the sequence to the first delay.

- Recycle timers are available in two configurations: symmetrical and asymmetrical.

- In symmetrical timing, the on and off periods are equal. The length of the timing period is adjust-able but the time between the on and off operations remains constant. Flashers are an example of symmetrical timing.

- Asymmetrical timers allow independent adjustments for the on and off periods. They come equipped with individual on and off time adjustment knobs and use standard NO and NC contact symbols referenced to the timer that controls them.

Multifunction and PLC Timers

MULTIFUNCTION TIMER

The term multifunction timer refers to timers that perform more than one timing function. Multifunction timers are more versatile in that they can perform many different timing functions and therefore are more common.

PLC TIMERS

Programmable logic controllers (PLCs) can be programmed to operate like conventional timing relays. The PLC timer instruction can be used to activate or deactivate a device after a preset interval of time. One advantage of the PLC timer is that its timer accuracy and repeatability are extremely high. The most common types of PLC timer instructions are the on-delay timer (TON), off-delay timer (TOF), and retentive timer on (RTO).

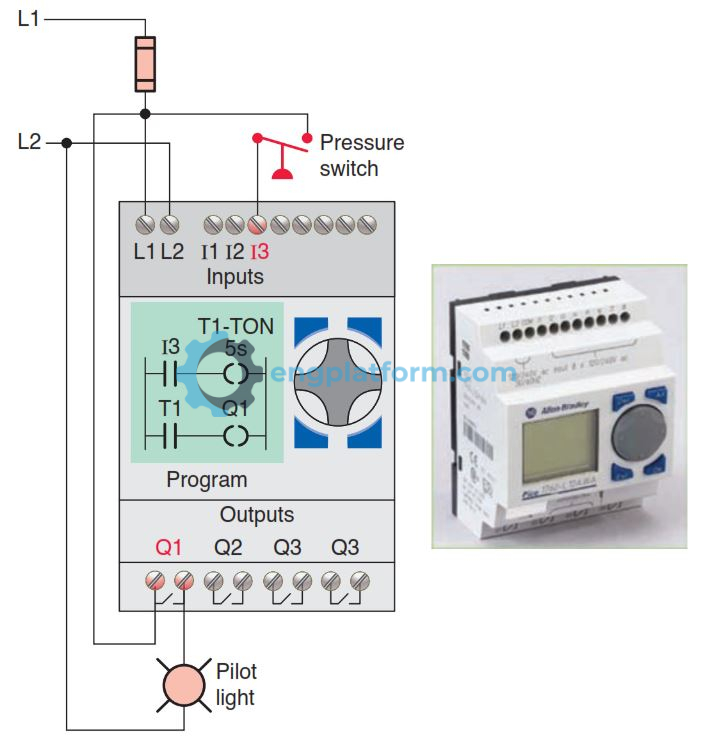

Figure below illustrates how an Allen-Bradley Pico programmable logic controller is wired and programmed to implement an on-delay timer function. This application calls for the pilot light to turn on any time the pressure switch closes for a sustained period of 5 seconds or more. The procedure followed can be summarized as follows:

- The pressure switch is hard-wired to input I3 and the pilot light output to Q1 according to the wiring diagram.

- Next, the ladder logic program is entered, using the front keypad and LCD display.

- When the pressure switch contacts close, the programmed timing coil T1 energizes, initiating the time-delay period.

- After 5 seconds have passed, programmed timer contact T1 closes to energize output relay coil Q1 and turn the pilot light on.

- Opening of the pressure switch contacts at any time resets the timed value to zero.