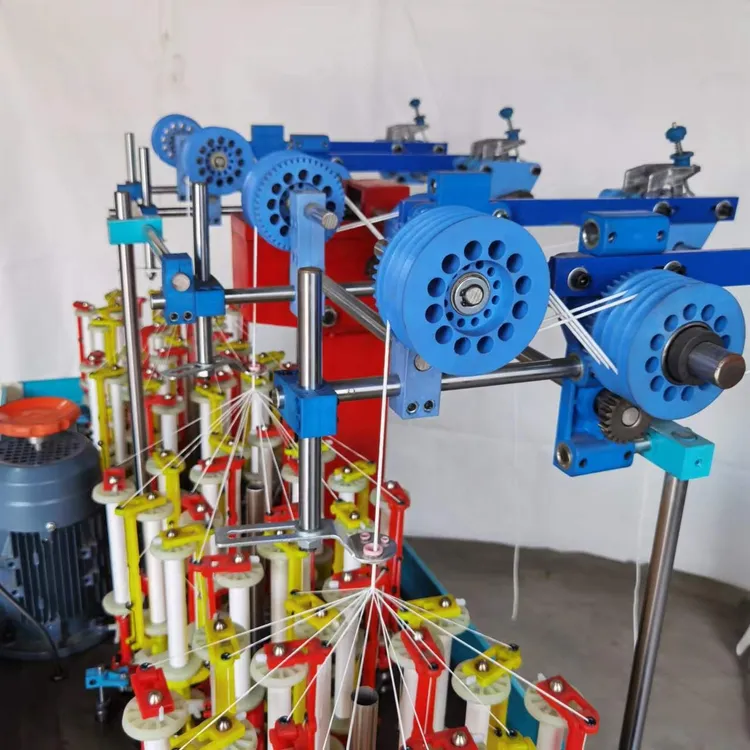

The weaving or twisting machine is a critical piece of equipment in the industrial production of cables, fabrics, and other textile-related products. With the advancement of technology, these machines have become symbols of modernization in manufacturing facilities worldwide. The image you provided depicts a complex machine featuring rotating spindles, thread reels, and a motor, indicating it is a specialized device used for twisting or weaving raw threads into finished products. Such machines are not only prevalent in the textile industry but are also widely utilized in the production of electrical wires, optical cables, and other industrial materials. In the context of Industry 4.0, enhancements in automation and precision have significantly boosted productivity and reduced errors, offering substantial economic benefits to businesses.

The emergence of weaving and twisting machines marked a turning point in manufacturing history, transitioning from traditional manual tools to automated systems. As of today, August 10, 2025, at 02:59 PM +07, manufacturers continue to innovate these machines to meet the growing demands of the market, particularly in fields requiring high precision, such as telecommunications cable production or technical fabrics. The image reveals an industrially designed model, with components like the motor, control panel, and thread reels arranged systematically, reflecting the sophistication of its engineering.

Structure of the Machine

The weaving or twisting machine in the image comprises several key components, each playing an essential role in its operation. The machine’s frame, constructed from durable metal such as steel or an alloy, provides a sturdy foundation to support other elements like the motor, spindles, and thread reels. This robust frame ensures stability and resilience in demanding industrial environments.

At the heart of the machine lies the motor, which powers the entire system. In the image, the motor is encased in metal and connected to a gear system that transfers motion to the spindles. The spindles, painted in red and yellow, are mounted on rotating holders, allowing threads to be pulled and twisted in an organized manner. These reels are designed to hold multiple threads, which are then processed simultaneously to create a cohesive product.

The gear and belt system, visible at the top of the machine, facilitates the transmission of power from the motor to the spindles. The red and white belts help regulate speed and ensure synchronization among the thread reels. Additionally, the control panel at the machine’s base features buttons and a digital display, enabling operators to adjust parameters and monitor performance. The red and green buttons likely serve as power switches or emergency stops, a crucial safety feature in industrial settings.

Functions of the Machine

The primary function of this machine is to twist or weave raw threads into a finished product. The twisting process occurs as the thread reels rotate in opposite or synchronized directions, depending on the machine’s settings, to produce a stronger, more uniform thread structure. This is particularly important in manufacturing electrical cables or optical fibers, where durability and flexibility are paramount. The machine also allows for tension adjustment, ensuring the output thread is neither too tight nor too loose.

Another key function is the automated drawing of threads from raw reels to finished spools. The gear system and motor are programmed to maintain a consistent speed, minimizing human intervention. The control panel enables operators to input parameters such as rotation speed, twists per minute, and thread length, optimizing efficiency. This automation is especially valuable in large-scale factories where mass production is a priority.

Applications of the Machine

The weaving or twisting machine has diverse applications depending on the type of thread and intended use. In the textile industry, it is employed to produce fabrics from cotton, polyester, or synthetic fibers, creating durable materials with intricate patterns. In the electrical sector, the machine is used to manufacture cables and optical fibers, where copper or glass fibers are twisted to enhance conductivity or signal transmission.

Furthermore, the machine is applied in the production of ropes and cables for construction and maritime purposes. Its ability to adjust the number of threads and twist levels allows for tailored products to meet specific project requirements. In the modern era, with increasing demand for high-tech materials, the machine has been adapted to produce specialized fibers such as carbon or aramid fibers, used in aerospace and defense industries.

Basic Technical Specifications

Based on the image and analysis, the following are approximate technical specifications for this type of machine (note that exact values may vary by manufacturer):

- Motor Power: Approximately 1.5 – 3 kW, depending on the machine’s size.

- Rotation Speed: 500 – 1500 revolutions per minute, adjustable via the control panel.

- Number of Thread Reels: 8 – 12 reels, depending on the design.

- Output Thread Length: Up to 1000 meters per run, depending on raw reel size.

- Power Supply: 220V or 380V, 50/60Hz, compliant with industrial standards.

- Machine Dimensions: Approximately 1.5m x 1m x 1.5m (length x width x height), subject to model variations.

- Weight: 300 – 500 kg, depending on materials and structure.