Forming plastic is the process of transforming a specified material into a desired shape. Raw plastic, or resin, is usually in the form of pellets, powder, liquid components, or sheets. The processes listed below describe the transformation from raw material to manufactured part.

Blow molding is a process whereby a softened plastic tube inflates against mold walls and hardens by cooling, typically to form a hollow vessel or container. The three primary types of blow molding are extrusion, injection, and stretch. The selected method is dependent on part size, quantity, and desired level of finish.

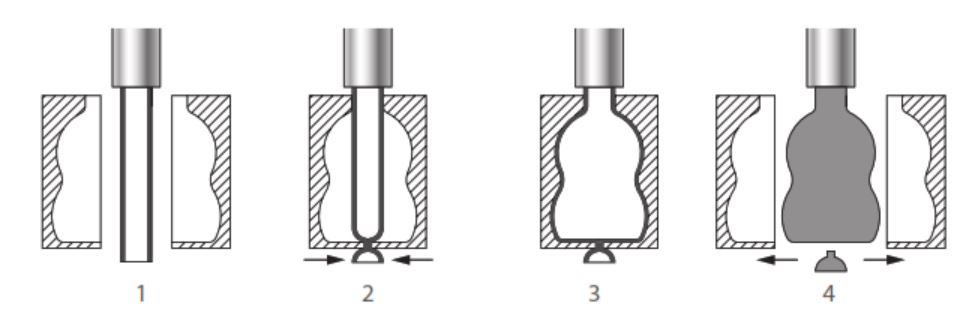

Extrusion blow molding is a process in which a heat-softened, tubular pari- son extrudes to the proper length; a two-part mold encloses it, and pinches off the bottom, thereby sealing the parison; air is blown in, expanding the parison against the mold; and after the part cools the mold opens, the hardened part is removed, and excess material is trimmed. Typically, this is the process used for low- volume production on containers greater than 12 ounces.

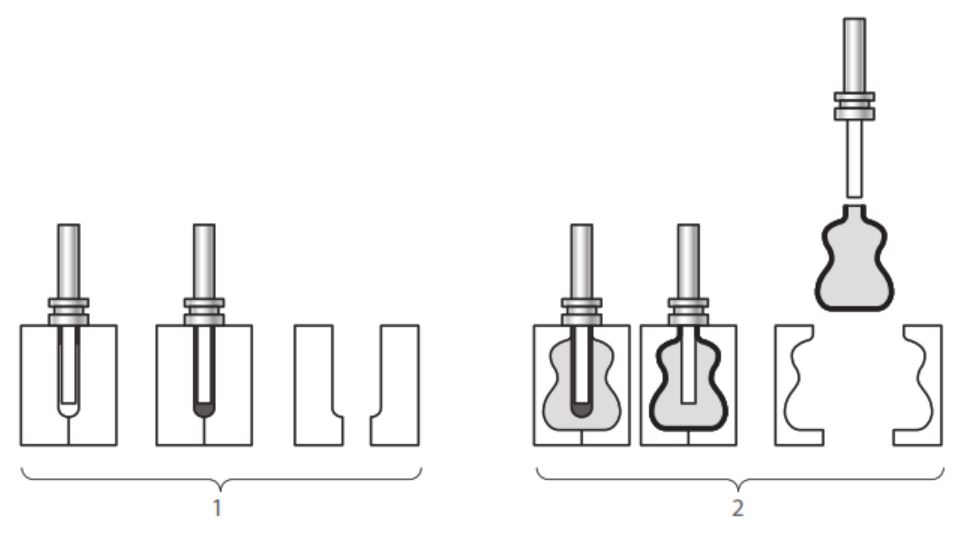

Injection blow molding is a process in which a test tube–shaped injection-mold- ed parison is premolded and transferred into the blow mold while it is still hot; air is blown in, expanding the parison against the mold walls; and the cooled, hardened part is removed from the mold. The process does not require finishing, and yields parts with accurate wall thickness and high-quality neck finish. This is the process used for smaller bottles and containers in high volumes and with high levels of detail and finish.

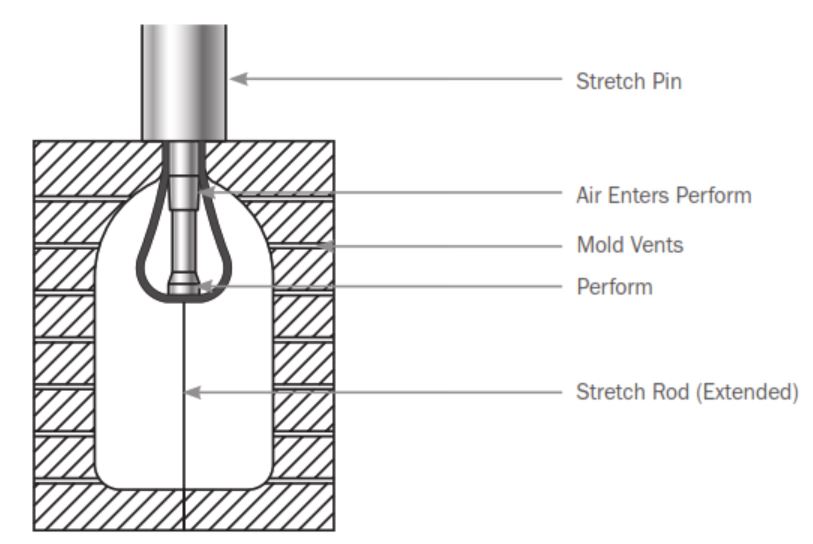

Stretch blow molding is a process in which a preformed parison is transferred to a mold while it is still hot, with an internal rod that is part of the mold; as the rod extends into the mold, it stretches the parison, elongating it, and simultaneously blows air into it, expanding it against the mold walls; and the cooled, hardened finished part is removed from the mold and does not require finishing. This is the process used for larger volume containers such as 2-liter beverage bottles.

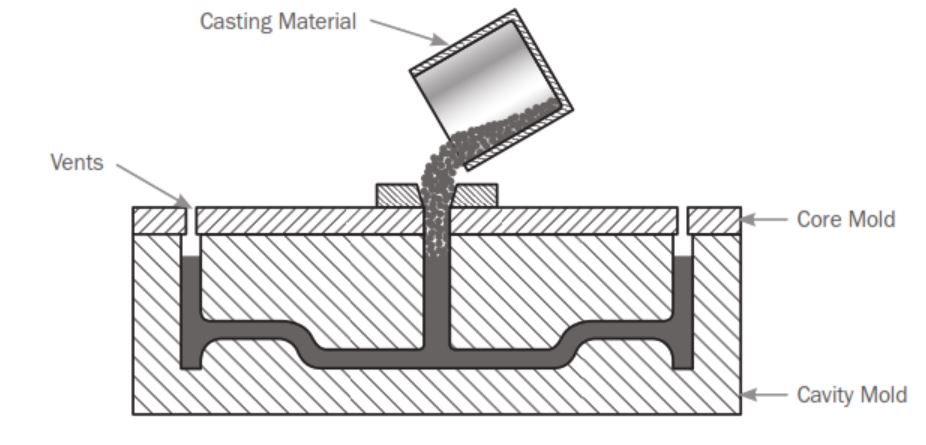

Casting is a process by which liquid plastic (usually two-part epoxy) is poured into a mold and allowed to harden. This process is used for low-volume production where highly detailed parts are needed but cost is less important. Tooling may be made of a rigid material or flexible RTV (room-temperature vulcanized rubber). Undercuts may be included in a part when a flexible mold is used, since the flex allows parts to be removed.

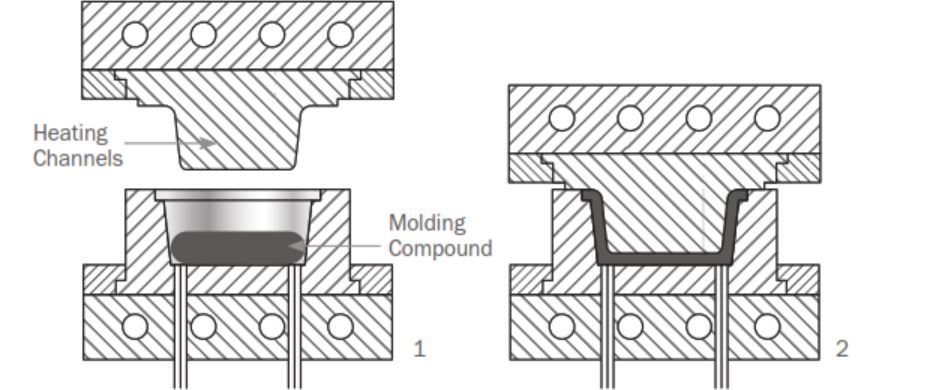

Compression molding is a process by which a measured amount of thermoset plastic or elastomer is placed in a heated mold and compressed into the desired shape. The mold holds the compressed material until it hardens. Automotive components, container caps (such as cosmetics), and dinnerware commonly use this molding method. Flash may form at the parting line and requires a secondary trim operation. Long dwell times and hand labor usually add to the cost of compression-molded parts.

Extrusion is a process by which heat-softened plastic is forced through a die to produce a continuous linear part, constant in section. Hard plastic pellets (resin), which are selected based on the desired material and color, move from a hopper through a screw-type driver and are heated to the point of melting, becoming a viscous liquid. The softened plastic is forced through an extrusion die to create the desired section and then is hardened by cooling. Once the extrusion is hardened, it is cut to the desired length

Uniform wall thicknesses are important to produce a straight extrusion, since varying section thicknesses can result in warpage. Intentional curvilinear extrusions can be achieved by adjusting the die geometry and rate of flow of the plastic. Dual extrusion bonds can also be achieved by feeding different thermoplastic materials through a common extrusion die.

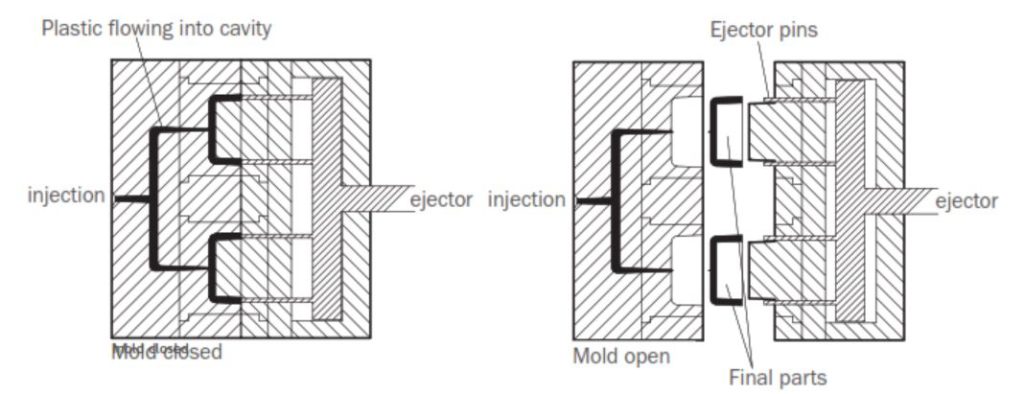

Injection molding is a process by which melted plastic is injected into a negative cavity and cooled to create a positive part. Injection-molded parts typically have a high level of finish and detail on exterior and interior surfaces.

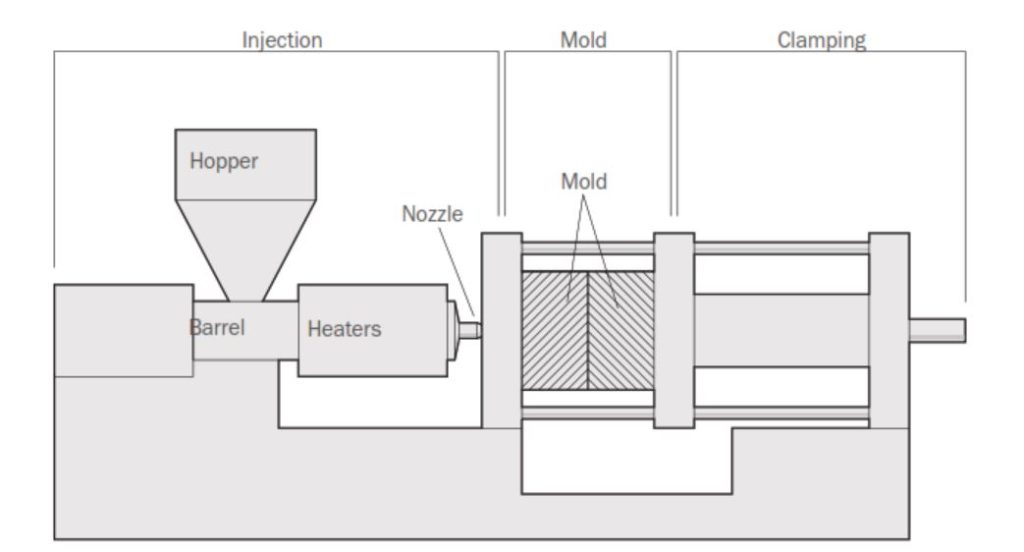

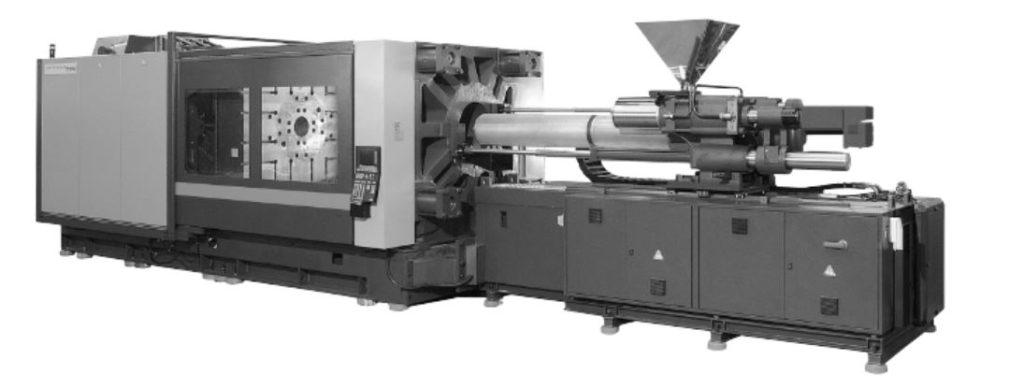

An injection-molding machine comprises three major functions/components:

- Injection Hard plastic pellets (resin) move from a hopper through a screw-type driver and are heated to the point of melting and becoming a liquid. The liquid plas- tic is forced through a nozzle into the mold. The pellets are selected based on the desired material and color.

- Mold A specially designed metal tool consisting of a “mold base” and one or more cavities. The cavities are contoured to the exact shape of the designed final part. The liquid plastic is forced into the cavity void where it cools and hardens. The mold can vary widely in size and complexity. The mold is removable, allowing one injection-molding machine to use different molds to produce different parts.

- Clamping applies force to open and close the mold closed during the injection process. When the new plastic part has cooled and hardened, the mold is opened and an ejector forces the part from the mold.

When designing an injection-molded part, designers should ensure that there is adequate draft (angle in the part to allow easy removal from the mold), there are no undercuts (which would make it impossible to remove from the mold), sharp corners are avoided (which may not fill properly), and a uniform wall thickness is maintained (to prevent uneven cooling, which can result in warpage). It is possible to include undercut-like features using shut-offs, slide-actions in the mold, cam blocks, or collapsible cores. These features add cost and complexity to the mold, but can add value, reduce parts count, or reduce labor costs. Variable wall thicknesses are possible, provided the thickest section is less than fifty percent thicker than the nominal (typical) wall section.

Final plastic parts will have a visible “gate,” which is the point where the liquid plastic was injected into the mold, and surface marks were created by the ejector pins. These features are designed to be on a less apparent surface (like the inside of the housing). Knit-lines (where two or more flows of melted plastic meet, cool, and harden) may also be visible if the pellets are not thoroughly mixed or if resins with metallic particles are used. Many parts also include structural ribs or raised bosses that assist in aligning with other parts and mounting components.

the mold

Injection molding can also accommodate many specialized processes. For example, it is possible to insert a specially designed part into the mold prior to injecting the liquid plastic (insert molding). The plastic hardens around the inserted part, resulting in a final part that is a combination of two materials, such as a housing with metal screw bosses. Also, because of the elasticity of plastic, built-in closure systems (living hinges and snap closures) can be designed into a part. It is also possible to mold a part in hard plastic, transfer it to a separate mold, and inject elastomer materials (overmolding) over entire surfaces or in specific locations.

produced, the type of material, and the cycle time, or the rate at which parts are produced

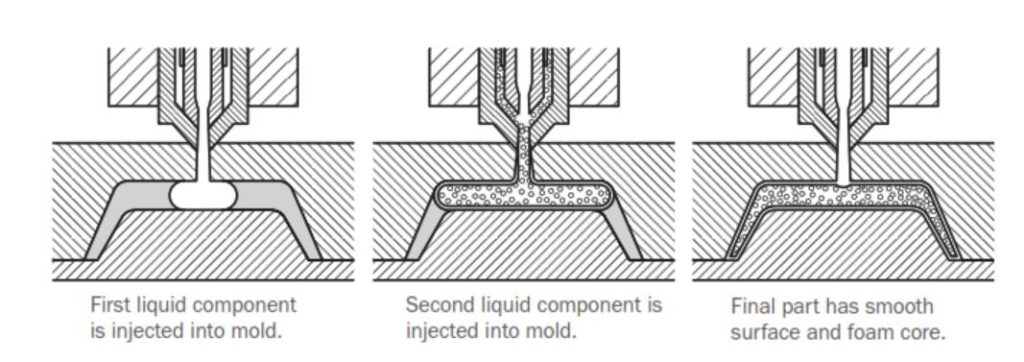

RIM (Reaction Injection Molding) is a process in which liquid resin and a catalyst are mixed in an injection-molding cavity. The two components chemically react to form a rigid part. This is the process used for automobile bumpers, electrical enclo- sures, enclosures for medical equipment, and other large, complex low-volume parts. This process allows for easy inclusion of inserts, is extremely rigid, and is wear resistant.

Rotational molding is a process by which a hollow mold is loaded with plastic resin, liquid, pellets, or powder, then heated externally and rotated to distribute the material evenly on the internal surface of the mold. When the mold cools, the rotation is stopped and the hardened part is removed. Parts produced with rotational molding have a highly finished exterior surface but limited sharpness in detail. The process is ideal for larger parts with no internal part features.

After a form is created that satisfies the users’ functional needs, simple considerations can help yield a higher-quality part. When designing a part for rotational molding, a designer should avoid large, flat surfaces, which have a tendency to warp. By using features such as ribs, crowns, steps, or domes, warpage can be minimized.Textured surfaces are also helpful in masking surface warpage (a glossy surface exaggerates slight surface variations). It is also recommended that the spacing between two parallel walls be greater than five times the nominal wall thickness of the part. Rotational molding tooling costs are relatively low, but cycle times are long (the process yields fewer parts in a given time than other processes).

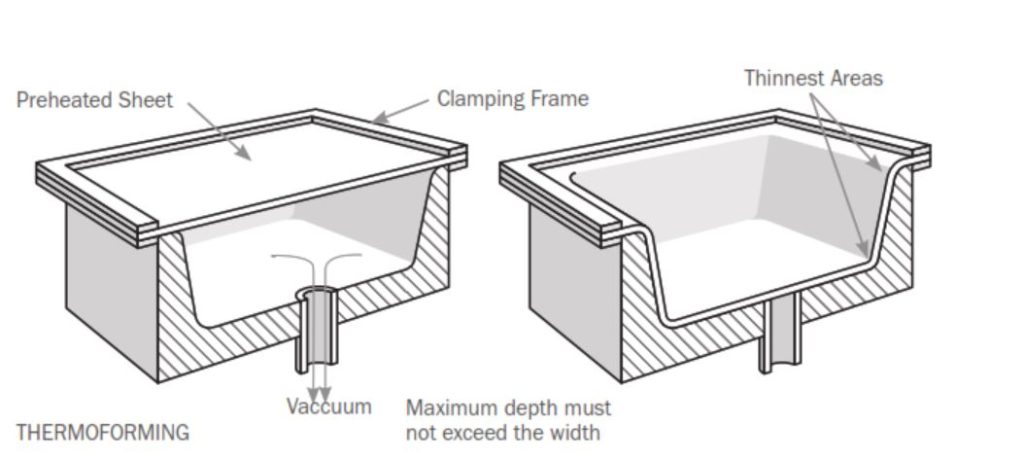

Thermoforming is a process by which a sheet of plastic is heated and forced into a mold cavity using vacuum or pressure (depending on the specific process).

When designing a thermoformed part, there are important considerations. First, the depth of the draw should be no greater than the largest dimension across the face. Next, an inside corner radius should be no less than 25 percent of the wall thickness. Finally, it is preferred that parts have a draft angle of one degree or greater. Thermoformed parts typically require secondary processes for trimming the part from the formed sheet or adding holes or slots. These processes are usually automated. Tooling costs are relatively low as molds can form from less expensive and more easily machined materials such as wood or aluminum.

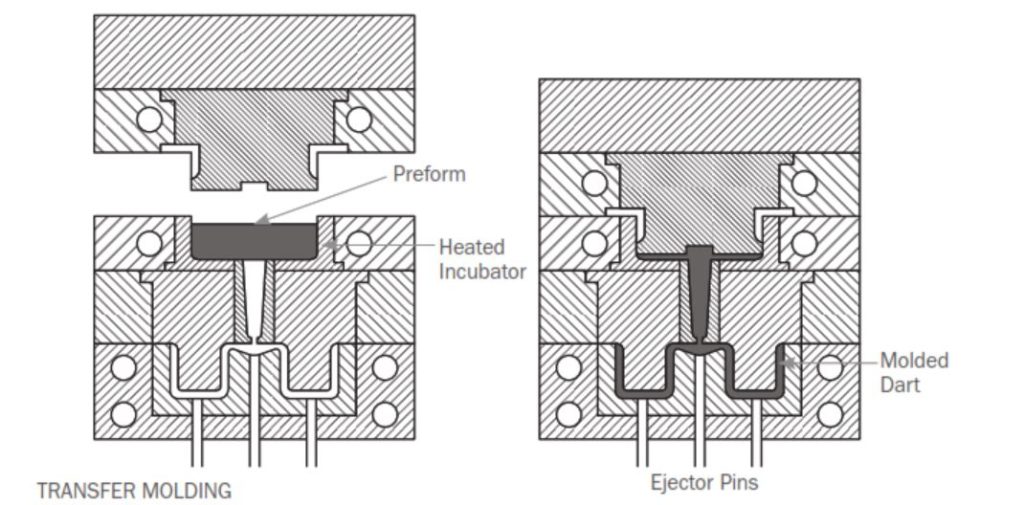

Transfer molding is a process in which thermoset plastic or elastomer is placed in a transfer chamber, heated, then injected into a mold cavity, where it cools and hardens. Because inserts are easy to use with this process, it is commonly used for two component parts, such as a rubber bushing molded around a fastener.

Urethane castings are produced using silicone or RTV (Room Temperature Vulcanization) molds. In some cases, a master pattern is created, scaled to compensate for shrinkage. In most cases, draft is not an issue and small undercuts are not a problem because the silicone mold is flexible. Cast urethane parts closely simulate final injection-molded plastic parts. The quality and finish of the final parts are identical to the level of finish of the master part; urethane castings can be molded in a selected color or painted.