Proper grounding practices protect people from the haz-ards of electric shock and ensure the correct operation of overcurrent protection devices. Intentional grounding is required for the safe operation of electrical systems and equipment. Unintentional or accidental grounding is considered a fault in electrical wiring systems or circuits.

“Grounding” is the intentional connection of a current-carrying conductor to the earth. For AC premises wiring systems in buildings and similar structures, this ground connection is made on the premise side of the service equipment and the supply source, such as a utility trans-former. The prime reasons for grounding are:

- To limit the voltage surges caused by lightning, utility system operations, or accidental contact with higher voltage lines.

- To provide a ground reference that stabilizes the voltage under normal operating conditions.

- To facilitate the operation of overcurrent devices such as circuit breakers, fuses, and relays under ground-fault conditions.

“Bonding” is the permanent joining together of metal parts that aren’t intended to carry current during normal operation, which creates an electrically conductive path that can safely carry current under ground fault conditions. The prime reasons for bonding are:

- To establish an effective path for fault current that facilitates the operation of overcurrent protective devices.

- To minimize shock hazard to people by providing a low-impedance path to ground. Bonding limits the touch voltage when non-current-carrying metal parts are inadvertently energized by a ground fault.

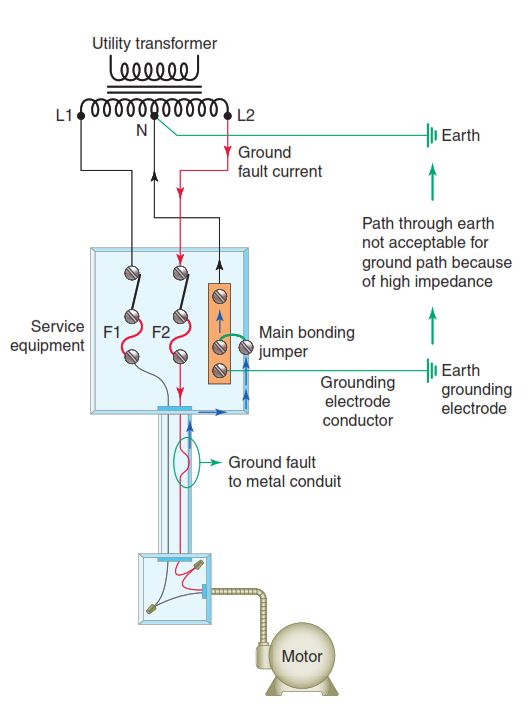

The Code requires all metal used in the construction of a wiring system to be bonded to, or connected to, the ground system. The intent is to provide a low impedance path back to the utility transformer in order to quickly clear faults. Figure 1-9 illustrates the ground fault current path required to ensure that overcurrent devices operate to open the circuit. The earth is not considered an effective ground fault current path. The resistance of earth is so high that very little fault current returns to the electrical supply source through the earth. For this reason the main bonding jumper is used to provide the connection between the grounded service conductor and the equipment grounding conductor at the service. Bonding jumpers may be located throughout the electrical system, but a main bonding jumper is located only at the service entrance. Grounding is accomplished by connecting the circuit to a metal underground water pipe, the metal frame of a building, a concreteencased elec-trode, or a ground ring.

A grounding system has two distinct parts: system grounding and equipment grounding. System grounding is the electrical connection of one of the current carrying conductors of the electrical system to the ground. Equipment grounding is the electrical connection of all the metal parts that do not carry current to ground. Conductors that form parts of the grounding system include the following:

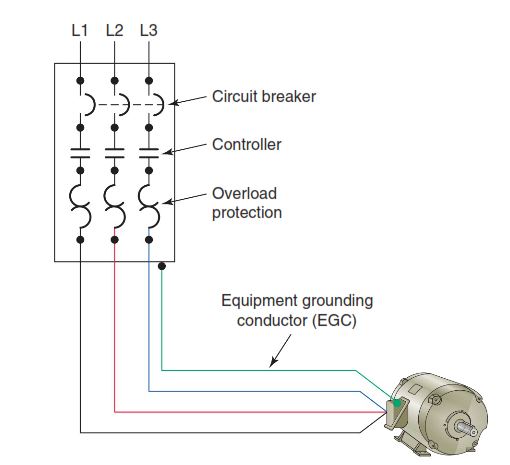

Equipment grounding conductor (EGC) is an electrical conductor that provides a low impedance ground path between electrical equipment and enclosures within the distribution system. Figure 1-10 shows the connection for an EGC. Electrical motor windings are normally insulated from all exposed non-current-carrying metal parts of the motor. How-ever, if the insulation system should fail, then the motor frame could become energized at line voltage. Any person contacting a grounded surface and the energized motor frame simultaneously could be severely injured or killed. Effectively grounding the motor frame forces it to take the same zero potential as the earth, thus preventing this possibility.

Grounded conductor is a conductor that has been intentionally grounded.

Grounding electrode conductor is a conductor used to connect the equipment grounding conductor or the grounded conductor (at the service entrance or at the separately derived system) to the grounding electrode(s). A separately derived system is a system that supplies electrical power derived (taken) from a source other than a service, such as the secondary of a distribution transformer.

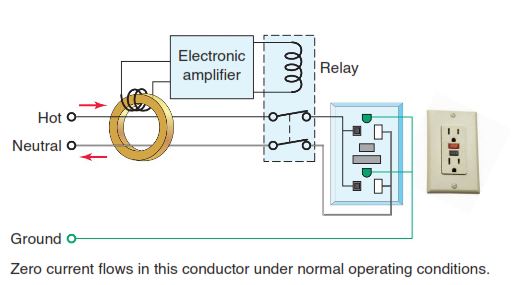

A ground fault is defined as an unintentional, elec-trically conducting connection between an ungrounded conductor of an electric circuit and the normally non-current-carrying conductors, metallic enclosures, metallic raceways, metallic equipment, or earth. The ground-fault circuit interrupter (GFCI) is a device that can sense small ground-fault currents. The GFCI is fast acting; the unit will shut off the current or interrupt the circuit within 1/40 second after its sensor detects a leakage as small as 5 milliamperes (mA). Most circuits are protected against overcurrent by 15 ampere or larger fuses or circuit breakers. This protection is adequate against short circuits and overloads. Leakage currents to ground may be much less than 15 amperes and still be hazardous.

Figure 1-11 shows the simplified circuit of a GFCI receptacle. The device compares the amount of current in the ungrounded (hot) conductor with the amount of current in the grounded (neutral) conductor. Under normal operating conditions, the two will be equal in value. If the current in the neutral conductor becomes less than the current in the hot conductor, a ground-fault condition exists. The amount of current that is missing is returned to the source by the ground fault path. Whenever the ground-fault current exceeds approximately 5 mA, the device automatically opens the circuit to the receptacle.

GFCIs can be used successfully to reduce electrical hazards on construction sites. The ground-fault protec-tion rules and regulations of OSHA have been determined necessary and appropriate for employee safety and health. According to OSHA, it is the employer’s responsibility to provide either (1) ground fault circuit interrupters on construction sites for receptacle outlets in use and not part of the permanent wiring of the building or structure or (2) a scheduled and recorded assured equipment grounding conductor program on construction sites, covering all cord sets, receptacles that are not part of the permanent wiring of the building or structure, and equipment connected by cord and plug that are available for use or used by employees.