Photoelectric Sensors

Photoelectric sensors are optical devices that detect changes in light intensity. They are used in a wide variety of applications, including security systems, industrial automation, robotics, automotive applications, and consumer electronics. Photoelectric sensors consist of two main components: a transmitter and a receiver. The transmitter emits a modulated light beam, which is then received by the receiver. The receiver decodes the light beam and switches the output device, which interfaces with the load. Photoelectric sensors are tuned to their emitter’s modulation frequency, so they only amplify the light signal that pulses at the specific frequency. This makes them less susceptible to interference from other light sources.

Most photoelectric sensors allow adjustment of the light sensitivity, which determines how much light is required to trigger the output. The response time of a photoelectric sensor is related to the frequency of the light pulses. Faster response times are required for applications where the sensor needs to detect very small objects or objects moving at high speeds.

- The transmitter contains a light source, usually an LED along with an oscillator.

- The oscillator modulates or turns the LED on and off at a high rate of speed.

- The transmitter sends this modulated light beam to the receiver.

- The receiver decodes the light beam and switches the output device, which interfaces with the load.

- The receiver is tuned to its emitter’s modulation frequency, and will only amplify the light signal that pulses at the specific frequency.

- Most sensors allow adjustment of how much light will cause the output of the sensor to change state.

- Response time is related to the frequency of the light pulses. Response times may become important when an application calls for the detection of very small objects, objects moving at a high rate of speed, or both.

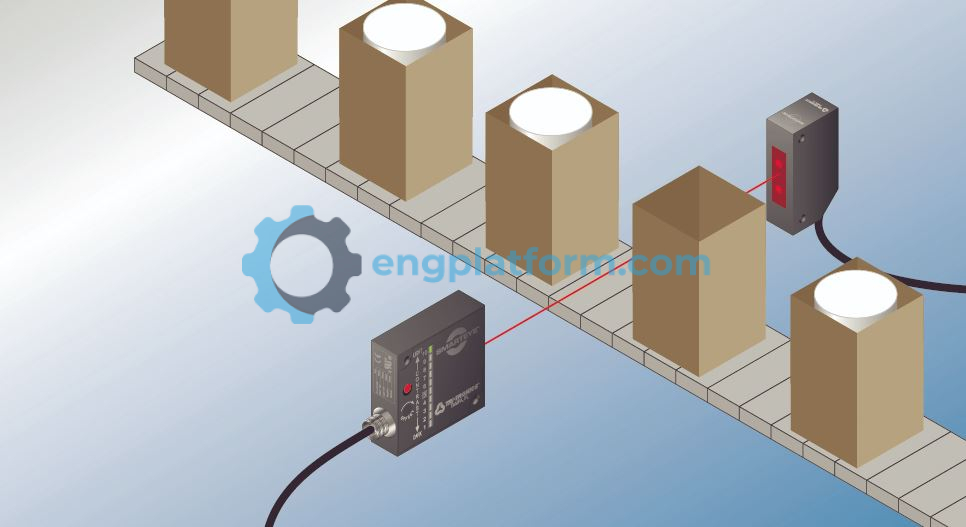

The scan technique is the method used by photoelectric sensors to detect an object. Common scan techniques include through-beam, retroreflective, and diffuse scan. Understanding the differences among the available photoelectric sensing techniques is important in determining which sensor will work best in a specific application.

THROUGH-BEAM SCANNING

Through-beam photoelectric sensors (also called direct scan sensors) are used to detect objects by placing the transmitter and receiver in direct line with each other. The object to be detected is placed in the path of the light beam, which blocks the light to the receiver and causes the receiver’s output to change state.

Through-beam sensors are a reliable method for detecting objects in areas of heavy dust, mist, and other types of air-borne contaminants that may disperse the beam. They are also well-suited for monitoring large areas, with a maximum sensing range of about 300 feet.

One common application of through-beam sensors is in garage door openers. A through-beam sensor is mounted near the floor, across the width of the door. When the door is closing, the sensor senses that nothing is in the path of the door. If the sensor detects an object in the path of the door, the door will stop closing.

RETROREFLECTIVESCANNING

The scan technique refers to the way a photoelectric sensor detects an object. The three most common scan techniques are through-beam, retroreflective, and diffuse.

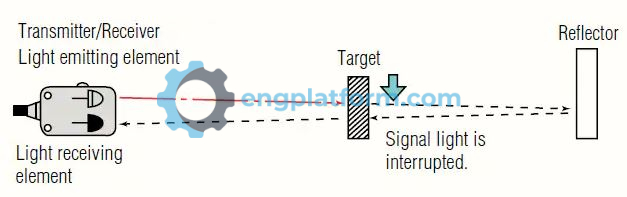

Through-beam sensors place the transmitter and receiver in direct line with each other. When an object passes between the transmitter and receiver, it blocks the light beam and triggers the sensor. Through-beam sensors have the longest sensing range, but they are also the most susceptible to interference from other light sources. Retroreflective sensors have a single unit that contains both the transmitter and receiver. The light beam is emitted from the sensor and reflected back by a reflector. When an object passes between the sensor and reflector, it blocks the reflected light beam and triggers the sensor. Retroreflective sensors are less susceptible to interference from other light sources than through-beam sensors, but they have a shorter sensing range.

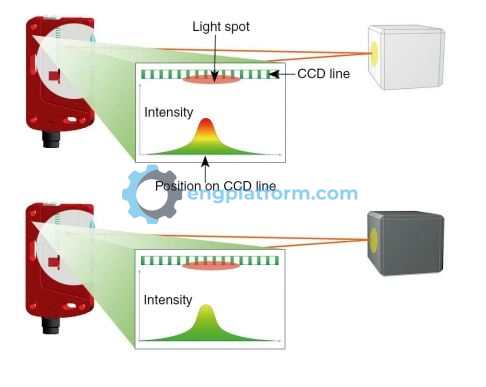

Diffuse sensors also have a single unit that contains both the transmitter and receiver. The light beam is emitted from the sensor and scattered by the object being detected. Some of the scattered light is reflected back to the sensor, which triggers the sensor. Diffuse sensors are the least susceptible to interference from other light sources, but they have the shortest sensing range of the three types of sensors.

The best type of photoelectric sensor for a particular application will depend on the specific requirements of the application. For example, if the sensor needs to detect objects over a long distance, a through-beam sensor may be the best choice. If the sensor needs to be used in an area with a lot of ambient light, a diffuse sensor may be the best choice.

Retroreflective scan sensors work by emitting a light beam and detecting the light that is reflected back from a reflector. However, they may not be able to detect shiny targets because shiny targets tend to reflect light in all directions, including back to the sensor. This can cause the sensor to be unable to distinguish between the light reflected from the target and the light reflected from the reflector. Polarized retroreflective scan sensors are a variation of retroreflective scan sensors that are designed to overcome this problem. Polarized retroreflective scan sensors use a polarizing filter to project the emitter’s beam in one plane only. This means that the light emitted from the sensor is polarized.

A corner-cube reflector is used to rotate the light reflected back to the receiver. The corner-cube reflector is designed to reflect light back in the same direction as it came from, regardless of the angle of incidence. The polarizing filter on the receiver only allows rotated light to pass through. This means that the receiver will only detect light that has been reflected by the corner-cube reflector. Shiny targets will not be able to reflect light back to the receiver, so they will not be detected by the sensor.

DIFFUSE SCANNING

A diffuse scan sensor, also known as a proximity scan sensor, is a type of photoelectric sensor that houses the transmitter and receiver in the same enclosure. Unlike retroreflective devices, diffuse scan sensors do not rely on reflectors to return the light signal to the receiver. Instead, light from the transmitter directly strikes the target, and the receiver picks up some of the diffused (scattered) light. When the receiver receives enough reflected light, the output will switch states. The operating range of a diffuse scan sensor is limited to a maximum of about 40 inches due to only a small amount of light reaching the receiver. The sensitivity of the sensor can be adjusted to detect an object or a specific point on an object that may be more reflective. This adjustment is often achieved using various colors with different reflective properties.

FIBEROPTICS

Fiber optics is not a scan technique, but another method for transmitting light. Fiber optic sensors use a flexible cable containing tiny fibers that channel light from emitter to receiver. Fiber optics can be used with through-beam, retroreflective scan, or diffuse scan sensors. In through-beam scan, light is emitted and received with individual cables. In retroreflective and diffuse scan, light is emitted and received with the same cable.

Fiber optic sensor systems are completely immune to all forms of electrical interference. The fact that an optical fiber does not contain any moving parts and carries only light means that there is no possibility of a spark. This means that it can be safely used even in the most hazardous sensing environments such as a refinery for producing gases, grain bins, mining, pharmaceutical manufacturing, and chemical processing. Another advantage of using optical fibers is the luxury it affords users to route them through extremely tight areas to the sensing location. Certain fiber optic materials, particularly the glass fibers, have very high operating temperatures (450°F and higher).