TACHOMETER

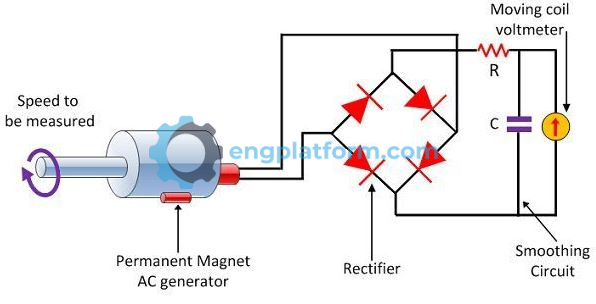

Tachometer generators are small devices that convert rotational speed into an electrical signal. This signal can be used to indicate or control the speed of a motor. Tachometer generators can be either AC or DC. DC tachometer generators have a permanent magnet field, while AC tachometer generators have a field that is excited by a constant AC supply.

In either case, the rotor of the tachometer generator is mechanically connected to the load. The rotor spins with the load, and its speed is proportional to the speed of the load. As the rotor spins, it generates an electrical voltage. The voltage is proportional to the speed of the rotor, and its phase or polarity depends on the direction of rotation. The electrical signal from the tachometer generator can be used to indicate or control the speed of the load. For example, it can be used to drive a speedometer or to control the speed of a motor.

MAGNETIC PICKUP

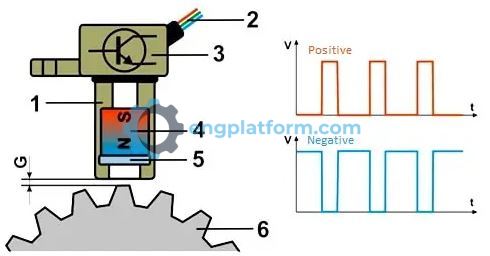

Magnetic pickups are used to measure the speed of a rotating shaft. They work by converting the motion of a ferromagnetic object, such as a gear tooth, into an electrical signal. A magnetic pickup consists of a coil wound around a permanent magnet. When a ferromagnetic object passes through the magnetic field, it creates a change in the magnetic flux. This change in flux induces a voltage in the coil.

The frequency of the voltage signal is proportional to the speed of the rotating shaft. This is because more ferromagnetic objects will pass through the magnetic field in a given time if the shaft is rotating faster. To measure the speed of the shaft, the frequency of the voltage signal is measured. This can be done using a variety of electronic devices, such as a frequency counter or a microcontroller.

ENCODER

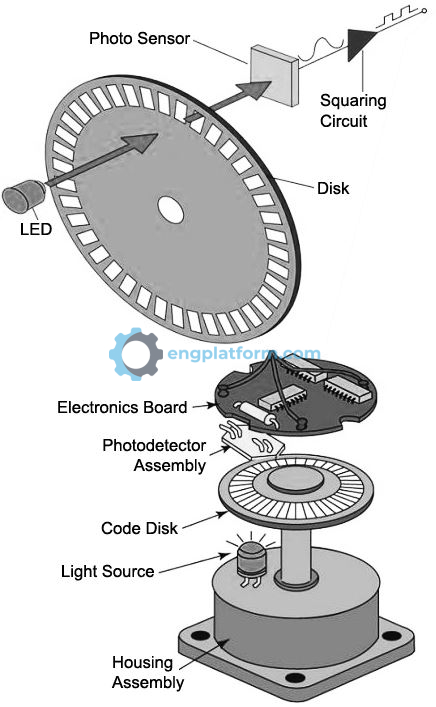

Encoders are devices that convert linear or rotary motion into a binary digital signal. This means that they can tell how far a shaft has rotated or how far a linear object has moved. Encoders are used in a wide variety of applications, including robotic control, industrial automation, and medical devices.

Encoders work by using a light source and a detector to detect the movement of a patterned disk. The disk is attached to the shaft or object that is being measured. As the shaft or object moves, the pattern on the disk interrupts the light beam. The detector counts the number of interruptions and generates a digital signal that represents the distance that the shaft or object has moved.

Encoders are very accurate and can be used to measure very small movements. They are also very reliable and can operate in harsh environments.