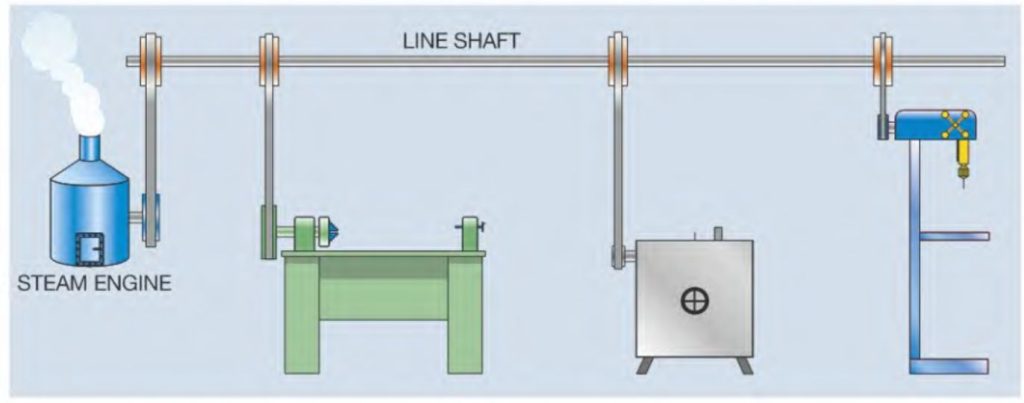

When installing electric motors and equipment, several factors should be considered. When a machine is installed, the motor, machine, and controls are all interrelated and must be considered as a unit. Some machines have the motor or motors and control equipment mounted on the machine itself when it is delivered from the manufacturer, and the electrician’s job is generally to make a simple power connection to the machine. Other types of machines require separately mounted motors that are connected by belts, gears, or chains. Some machines also require the connection of pilot-sensing devices such as photo switches, limit switches, or pressure switches. Regardless of how easy or complex the connection is, several factors must be considered.

Power source

One of the main considerations when installing a machine is the power source. Does the machine require single phase or three phase power to operate? What is the horsepower of the motor or motors to be connected? What is the amount of in-rush current that can be expected when the motor starts? Will the motor require some type of reduced voltage starter to limit inrush current? Is the existing power supply capable of handling the power requirement of the machine or will it be necessary to install a new power system?

Tire availability of power can vary greatly from one area of the country to another. Companies that supply power to heavily industrialized areas can generally permit larger motors to be started across-the-line than companies that supply power to areas that have light industrial needs. In some areas the power company may permit a motor of several thousand horsepower to be started across-the-line, and in other areas the power company may require a reduced voltage starter for motors rated no more than one hundred horsepower.

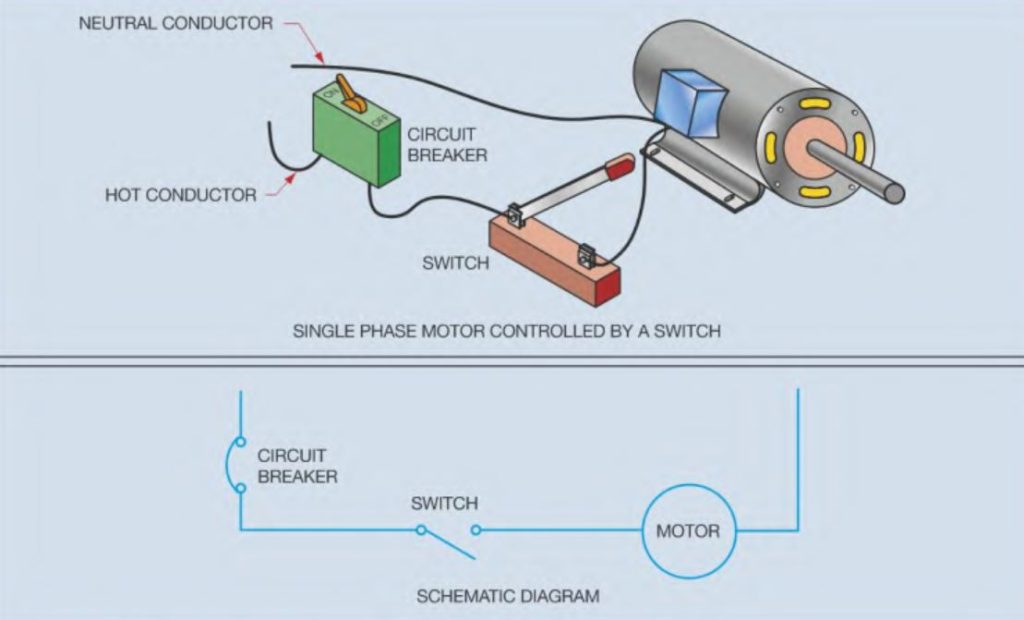

Motor Connections

When connecting motors, several factors should be considered, such as horsepower, service factor (SF), marked temperature rise, voltage, full load current rating, and NEMA Code letter. This information is found on the motor nameplate. The conductor size, fuse or circuit breaker size, and overload size are generally determined using the National Electrical Code® (NEC®) and/or local codes. Local codes

generally supersede the National Electrical Code® and should be followed when they apply. Motor installation based on the NEC® will be covered in this textbook.

ControllerType

Different operating conditions require different types of control. Some machines simply require the motor to start and stop. Some machines require a soft start, which means bringing the motor up to speed over a period of time instead of all at once. This is especially true of gear-driven machines or motors that must start heavy inertia loads, such as flywheels or centrifuges. Other machines may require variable speed or the application of a brake when the motor is stopped. Inching and jogging may also be a consideration. Regardless of the specific conditions, all control systems should be able to start and stop the motor, and also provide overload protection for the motor and shortcircuit protection for the circuit

Environment

Another consideration is the type of environment in which the motor and control system operates. Can the controls be housed in a general purpose enclosure or is the system subject to moisture or dust? Some locations may contain corrosive vapor or liquid, or extremes of temperature. All of these conditions should be considered when selecting motors and control components.

Codes and Standards

Another very important consideration is the safety of the operator and persons that work around the machine. In 1970, the Occupational Safety and Health Act (OSHA) was established. In general, OSHA requires employers to provide an environment that is free of recognized hazards that are likely to cause serious injury. Another organization that exhibits much influence on the electrical field is Underwriters Laboratories (UL). Insurance companies established Underwriters Laboratories in an effort to reduce the number of fires caused by electrical equipment. UL tests equipment to determine if it is safe under different conditions. Approved equipment is listed in its annual publication, which is kept current with bimonthly supplements.