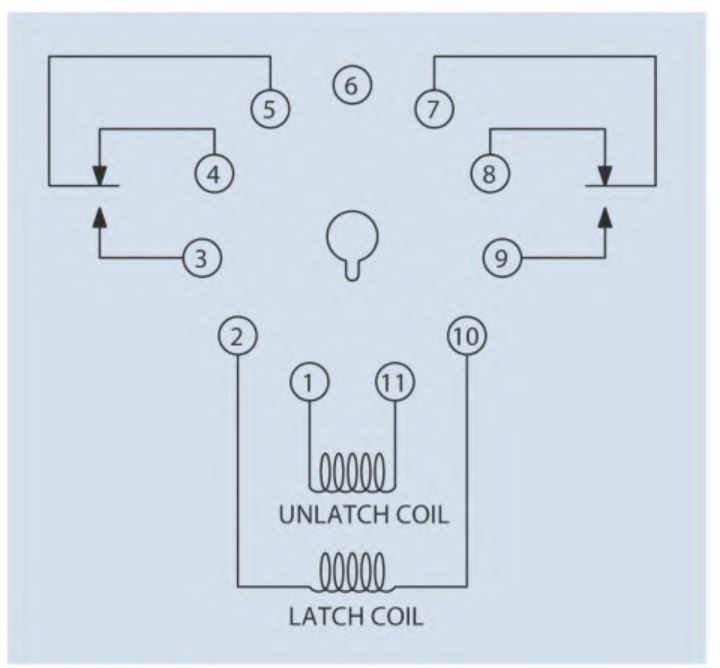

Mechanically held contactors and relays are often referred to as latching contactors or relays. They employ two electromagnets to operate. One coil is generally called the latch coil and the other is called the unlatch coil. The latch coil causes the contacts to change position and mechanically hold in position after power is removed from the latch coil. To return the contacts to their normal de-energized position, the unlatch coil must be energized. Power to both coils is momentary. The coils of most mechanically held contactors and relays are intended for momentary use and continuous power often cause burnout. Unlike common magnetic contactors or relays, the contacts of latching relays and contacts do not return to a normal position if power is interrupted. They should be used only where there is danger of persons or equipment being harmed if power is suddenly restored after a power failure.

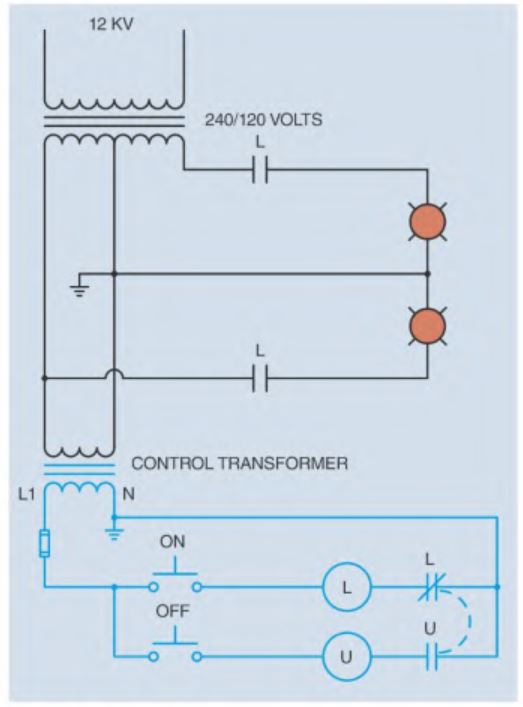

Sequence of Operation

Many latching type relays and contactors contain contacts that are used to prevent continuous power being supplied to the coil after it has been energized. These contacts are generally called coil clearing contacts.

Coil L is the latching coil and coil U is the unlatch coil. When the ON push button is pressed, current can flow to coil L, through normally closed contact L to neutral. When the relay changes to the latch position, the normally closed L contact connected in series with L coil opens and disconnects power to L coil. This disconnection prevents further power from being supplied to coil L. At the same time, the open U contact connected in series with coil U closes to permit operation of coil U when the OFF push button is pressed. When coil L energized, it also closed the L load contacts, energizing a bank of lamps. The lamps can be turned off by pressing the OFF push button and energizing coil U. This process causes the relay to return to the normal position. Notice that the coil clearing contacts prevent power from being supplied continuously to the coils of the mechanically held relay.