Proximity Sensors

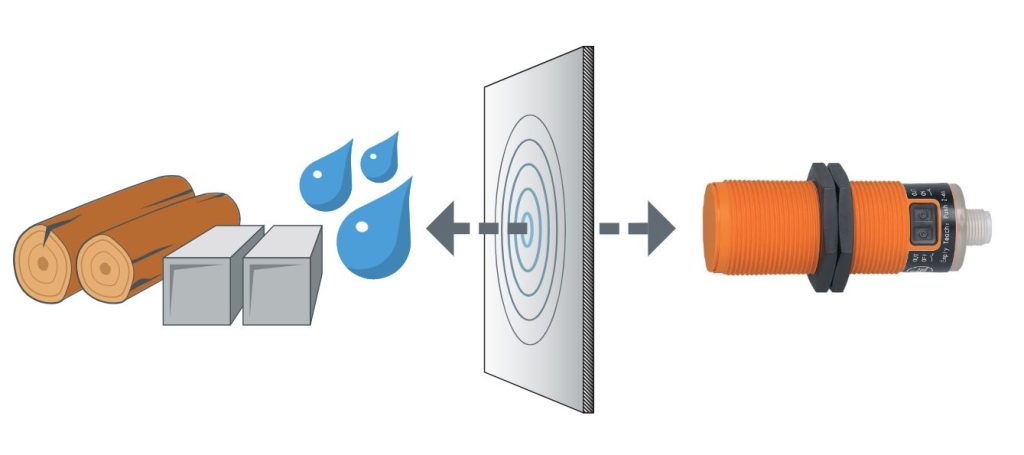

Proximity sensors detect the presence of objects without physical contact. They are used in a wide variety of applications, including industrial automation, robotics, and automotive systems. Proximity sensors work by sensing changes in magnetic or electrostatic fields. This allows them to detect the presence of solids such as metal, glass, and plastics, as well as most liquids.

Proximity sensors are available in various sizes and configurations, including the barrel type. Barrel type proximity sensors are housed in a metal or polymer barrel with threads on the outside of the housing. This allows the sensor to be easily adjusted on a mounting frame. Proximity sensors are completely encapsulated to protect against excessive vibration, liquids, chemicals, and corrosive agents found in the industrial environment.

INDUCTIVEPROXIMITYSENSORS

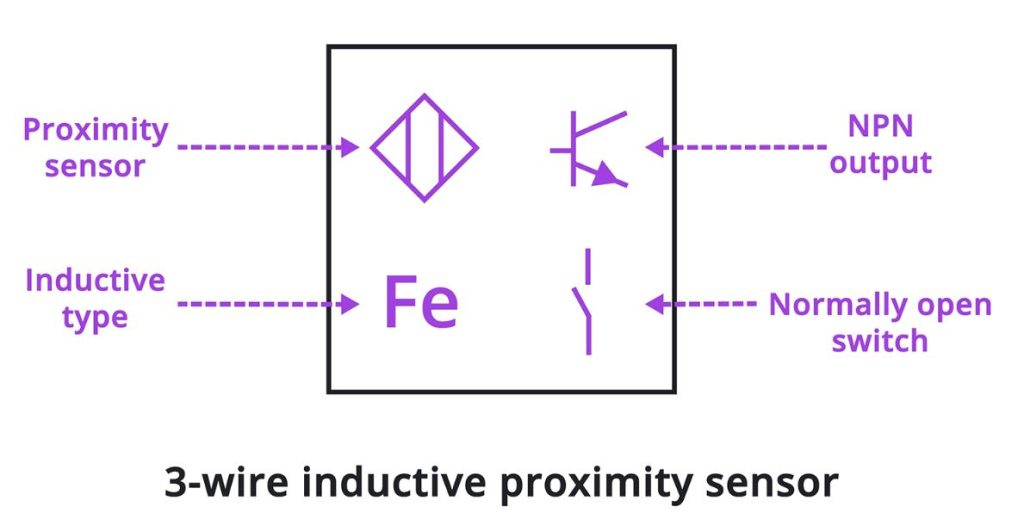

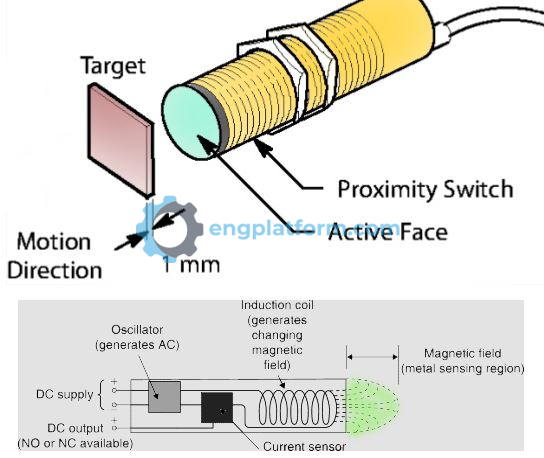

Proximity sensors operate on different principles, depend-ing on the type of matter being detected. When an application calls for noncontact metallic target sensing, an inductive-type proximity sensor is used. Inductive proximity sensors are used to detect both ferrous metals (containing iron) and nonferrous metals (such as copper, aluminum, and brass).

Inductive proximity sensors operate under the electrical principle of inductance, where a fluctuating current induces an electromotive force (emf) in a target object.

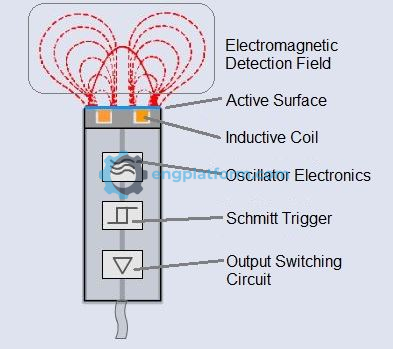

- The oscillator circuit generates a high-frequency electromagnetic field that radiates from the end of the sensor.

- When a metal object enters the field, eddy currents are induced in the surface of the object.

- The eddy currents on the object absorb some of radiated energy from the sensor, resulting in a loss of energy and change of strength of the oscillator.

- The sensor’s detection circuit monitors the oscillator’s strength and triggers a solid-state output at a specific level.

- Once the metal object leaves the sensing area, the oscillator returns to its initial value.

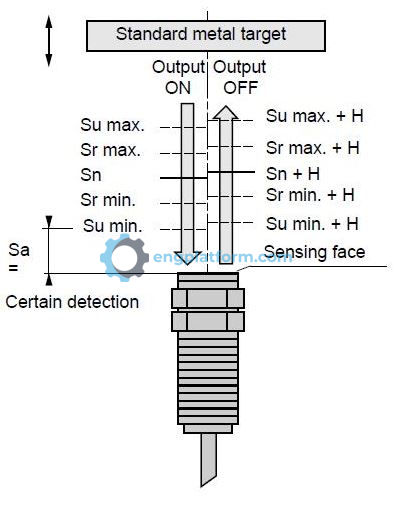

Proximity sensors can detect objects from a distance. The distance at which the sensor can detect an object depends on the type of metal and the size of the object. Ferrous metals can be detected from up to 2 inches away, while most nonferrous metals require a shorter distance, usually within an inch. The point at which the proximity sensor detects an object is called the operating point. The point at which the proximity sensor no longer detects the object is called the release point.

Most proximity sensors have an LED status indicator to show whether the sensor is detecting an object. The area between the operating point and the release point is called the hysteresis zone. Hysteresis is necessary to prevent the sensor from chattering (switching on and off rapidly) when subjected to shock and vibration, slow-moving targets, or minor disturbances such as electrical noise and temperature drift.

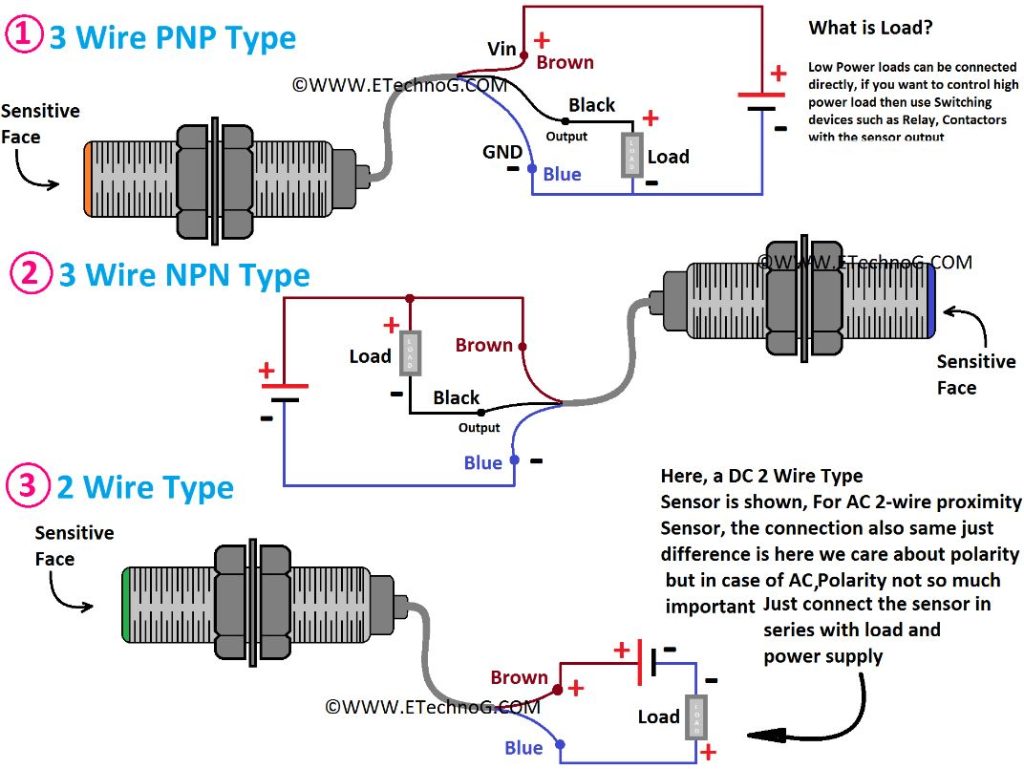

Proximity sensors are typically powered by either 24V DC or 120V AC. Three-wire DC proximity sensors have a positive lead, a negative lead, and a signal lead. When the sensor is actuated, the signal lead is connected to the positive lead if the sensor is normally open. If the sensor is normally closed, the signal lead is disconnected from the positive lead.

Proximity sensors can be either AC or DC powered. In the off state, a small amount of current must flow through the circuit to keep the sensor active. This is called the leakage current and is typically between 1 and 2 mA. When the sensor is actuated, it conducts the normal load circuit current. Proximity sensors are pilot devices, which means that they are used to switch on and off other devices, such as starters, contactors, and solenoids. They should not be used to directly operate a motor.

CAPACITIVEPROXIMITYSENSORS

Capacitive proximity sensors are similar to inductive proximity sensors. The main differences between the two types are that capacitive proximity sensors produce an electrostatic field instead of an electromagnetic field and are actuated by both conductive and nonconductive materials. Capacitive sensors contain a high-frequency oscillator along with a sensing surface formed by two metal electrodes.

- When the target nears the sensing surface, it enters the electrostatic field of the electrodes and changes the capacitance of the oscillator.

- As a result, the oscillator circuit begins oscillating and changes the output state of the sensor when it reaches a certain amplitude.

- As the target moves away from the sensor, the oscillator’s amplitude decreases, switching the sensor back to its original state.

Capacitive proximity sensors can detect both metal and nonmetallic materials, such as paper, glass, liquids, and cloth. They typically have a short sensing range of about 1 inch, regardless of the type of material being sensed. The dielectric constant of a material is a measure of how easily it can be polarized by an electric field. The higher the dielectric constant, the easier it is for the capacitive sensor to detect the material.

The capacitive proximity sensor is used to detect liquid inside a cardboard container. The liquid has a much higher dielectric constant than the cardboard container, which allows the sensor to “see through” the container and detect the liquid. When the sensor detects an empty container, it sends a signal to the push rod to divert the container.