Actuators are devices that convert an electrical signal into mechanical movement. Electromechanical relays are a type of actuator that mechanically switches electric circuits. Relays are important components of many motor control systems. They provide control logic by switching multiple control circuits. They are also used to control low-current pilot loads such as contactor and starter coils, pilot lights, and audible alarms.

In simpler terms, a relay is a switch that is controlled by an electrical signal. When the electrical signal is present, the relay closes the switch, allowing current to flow through the circuit. When the electrical signal is removed, the relay opens the switch, stopping current flow.

Relays are used in a wide variety of applications, including:

- Motor control systems

- Industrial automation

- Home automation

- Automotive systems

- Aerospace systems

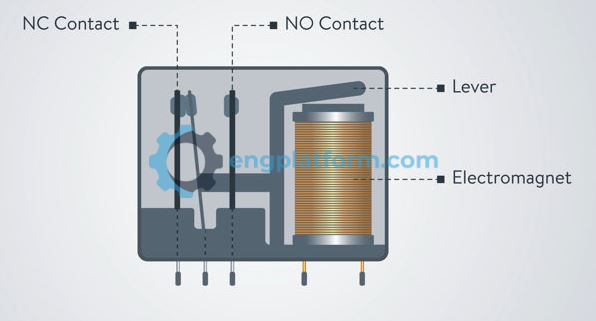

This relay consists of a coil, wound on an iron core, to form an electromagnet. When the coil is energized by a control signal, the core becomes magnetized and sets up a magnetic field that attracts the iron arm of the armature to it. As a result, the contacts on the armature close. When the current to the coil is switched off, the armature is spring-returned to its normal deenergized position and the contacts on the armature open.

The relay enables the energy in the motor high-power line circuit to be switched by a low-power two-wire proximity switch. In this example, the proximity switch operates a relay coil whose contacts operate motor starter coil M. The operation of the control circuit can be summarized as follows:

- With the switch on, anytime the proximity switch contacts close, relay coil CR will become energized.

- This in turn will cause the normally open CR contacts to close and complete the path of current to the M motor starter. The M motor starter energizes and closes the M contacts in the power circuit, starting the motor

- When the proximity switch opens, the CR coil deenergizes, opening CR contacts which in turn deenergizes coil M and opens the M contacts in the power circuit to stop the motor.

Double-break relay contacts use two pair of contacts that open the circuit in two places, creating two air gaps. It is analogous to having two contacts in series. Double-break contacts dissipate heat more readily, providing longer contact life and enabling the contact to handle higher voltages. Other benefits include greater DC load breaking capability and better isolation of contacts.

A dry contact refers to one that has both terminals available and in which neither contact is initially connected to a voltage source. When the starter coil is energized, the dry contact changes state and can be wired to devices or circuits that are separate from the motor starter circuit.