Solenoids

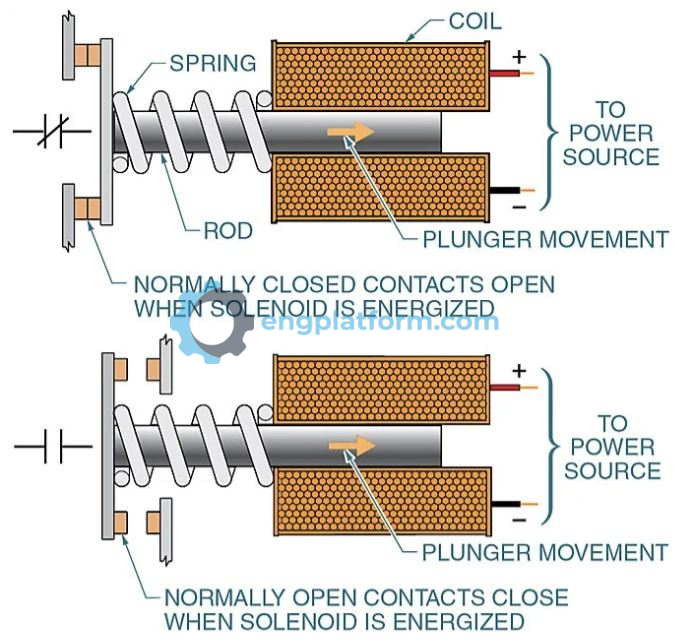

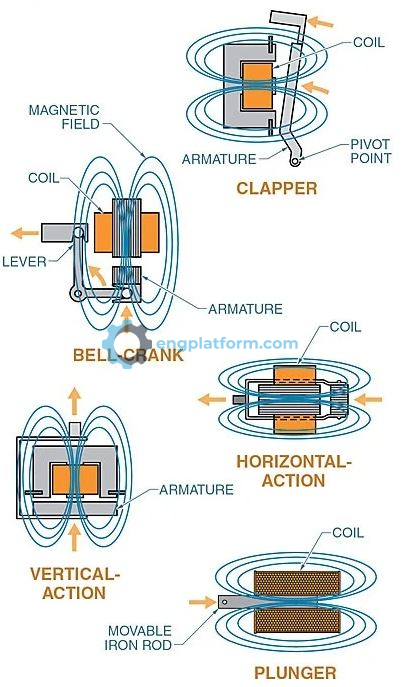

Electromechanical solenoids are devices that use electrical energy to create a magnetic field, which in turn causes mechanical movement. A solenoid consists of a coil, a frame, and a plunger (also called an armature). The coil and frame are the fixed parts of the solenoid. When the coil is energized, it produces a magnetic field that attracts the plunger, pulling it into the frame and creating mechanical motion. When the coil is de-energized, the plunger returns to its normal position due to gravity or the assistance of springs inside the solenoid.

AC-operated solenoids have laminated frames and plungers instead of solid iron pieces to reduce eddy currents induced by the magnetic field. Eddy currents are small currents that flow in the opposite direction of the main current. They waste energy and generate heat. Lamination breaks up the eddy currents and reduces their effect.

The choice of using DC- or AC-operated solenoid coils is usually predetermined by the type of supply voltage available. Most solenoid applications use DC. Differences between DC- and AC-operated solenoids include:

- AC solenoids tend to be more powerful in the fully open position than DC. This is due to inrush current, which at maximum stroke can be more than 10 times the closed current.

- The coil current for DC solenoids is limited by coil resistance only. The resistance of an AC solenoid coil is very low, so current flow is primarily limited by the inductive reactance of the coil.

- AC solenoids must close completely so that the inrush current falls to its normal value. If an AC solenoid plunger sticks in the open position, a burnout of the coil is likely. DC solenoids take the same current throughout their stroke and cannot overheat through incomplete closing.

- AC-operated solenoids are usually faster than DC, but with a few milliseconds variation in response time, depending on the point of the cycle when the solenoid is energized. DC solenoids are slower but they repeat their closing times accurately against a given load.

- A good AC solenoid, correctly used, should be quiet when closed, but only because its fundamental ten-dency to hum has been overcome by correct design and accurate assembly. Dirt on the mating faces or mechanical overload may make it noisy. A DC solenoid is naturally quiet.

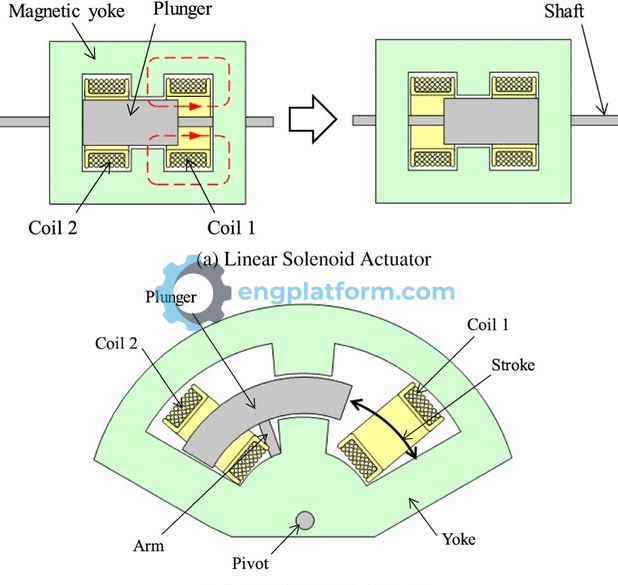

There are two main categories of solenoids: linear and rotary. The direction of movement, either rotary or linear, is based on the mechanical assembly within which the electromagnetic circuit is encased. Rotary solenoids incorporate a mechanical design that converts linear motion to rotary motion. Linear solenoids are usually classified as pull (the electromagnetic path pulls a plunger into the solenoid body) or push (the plunger shaft is pushed out of the frame case).

Solenoid Valves

Solenoid valves are devices that control the flow of liquids, gases, steam, and other media. They work by passing an electrical current through a solenoid, which changes the state of the valve. The valve body contains an orifice in which a disk or plug is positioned to restrict or allow flow. Flow through the orifice is either restricted or allowed depending on whether the solenoid coil is energized or deenergized. When the coil is energized, the core is drawn into the solenoid coil to close the valve. The spring returns the valve to its original open position when the current coil is deenergized. A valve must be installed with direction of flow in accordance with the arrow cast on the side of the valve body.

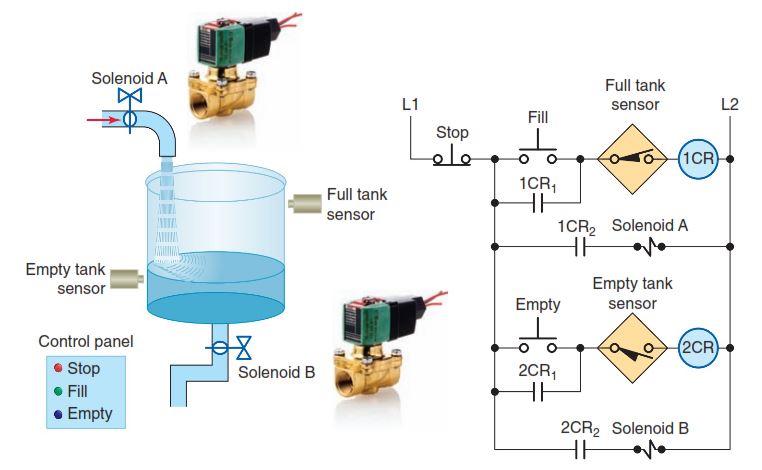

Solenoid valves are commonly used as part of tank filling and emptying processes. The operation of the control circuit can be summarized as follows:

- Assuming the liquid level of the tank is at or below the empty level mark, momentarily pressing the FILL push button will energize control relay 1CR.

- Contacts 1CR1 and 1CR2 will both close to seal in the 1CR coil and energize normally closed solenoid valve A to start filling the tank.

- As the tank fills, the normally open empty-level sensor switch closes.

- When the liquid reaches the full level, the normally closed full-level sensor switch opens to open the circuit to the 1CR relay coil and switch solenoid valve A to its deenergized closed state.

- Any time the liquid level of the tank is above the empty level mark, momentarily pressing the EMPTY push button will energize control relay 2CR.

- Contacts 2CR1 and 2CR2 will both close to seal in the 2CR coil and energize normally closed solenoid valve B to start emptying the tank.

- When the liquid reaches the empty level, the normally open empty level sensor switch opens to open the circuit to the 2CR relay coil and switch solenoid valve B to its deenergized closed state.

The stop button may be pressed at any time to halt the process.