Temperature sensors are devices that measure temperature. There are many different types of temperature sensors, each with its own unique technology and configuration. The four most common types of temperature sensors used today are:

- Thermocouples use the Seebeck effect to generate a voltage proportional to the temperature difference between two junctions.

- Resistance temperature detectors (RTDs) use the change in electrical resistance of a material with temperature to measure temperature.

- Thermistors use the change in electrical resistance of a semiconductor material with temperature to measure temperature.

- IC sensors use integrated circuit technology to measure temperature.

Each type of temperature sensor has its own advantages and disadvantages. Thermocouples are very durable and can operate in a wide range of temperatures, but they are less accurate than other types of temperature sensors. RTDs are more accurate than thermocouples, but they are more fragile and have a narrower temperature range. Thermistors are very sensitive and can measure very small changes in temperature, but they are also less accurate than other types of temperature sensors. IC sensors are the most accurate type of temperature sensor, but they are also the most expensive.

THERMOCOUPLE

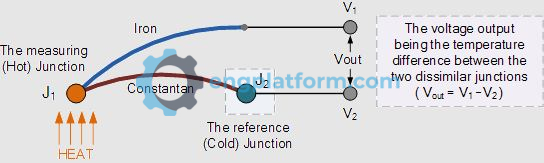

A thermocouple (TC) is a sensor that measures temperature. The thermocouple is by far the most widely used temperature sensor for industrial control. Thermocouples operate on the principle that when two dissimilar metals are joined, a predictable DC voltage will be generated that relates to the difference in temperature between the hot junction and the cold junction. The hot junction (measuring junction) is the joined end of a thermocouple that is exposed to the process where the temperature measurement is desired. The cold junction (reference junction) is the end of a thermocouple that is kept at a constant temperature to provide a reference point. For example, a K-type thermocouple, when heated to a temperature of 300°C at the hot junction, will produce 12.2 mV at the cold junction.

The signal produced by a thermocouple is a function of the difference in temperature between the probe tip (hot junction) and the other end of the thermocouple wire (cold junction). For this reason it is important that the cold (or reference) junction be maintained at a constant known temperature to produce accurate temperature measurements. In most applications the cold junction is maintained at a known (reference) temperature, while the other end is attached to a probe.

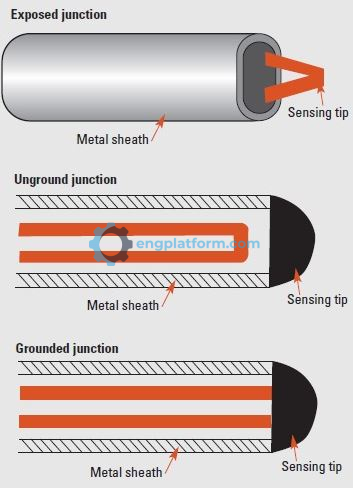

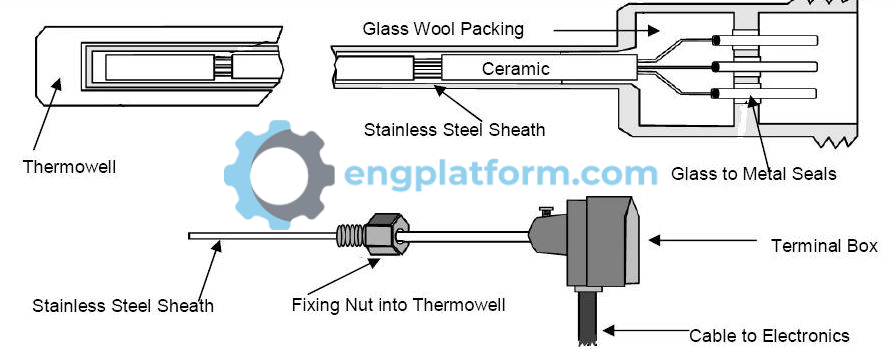

A thermocouple probe consists of thermocouple wire housed inside a metallic tube. The wall of the tube is referred to as the sheath of the probe. The tip of the thermocouple probe is available in three different styles: grounded, ungrounded, and exposed.

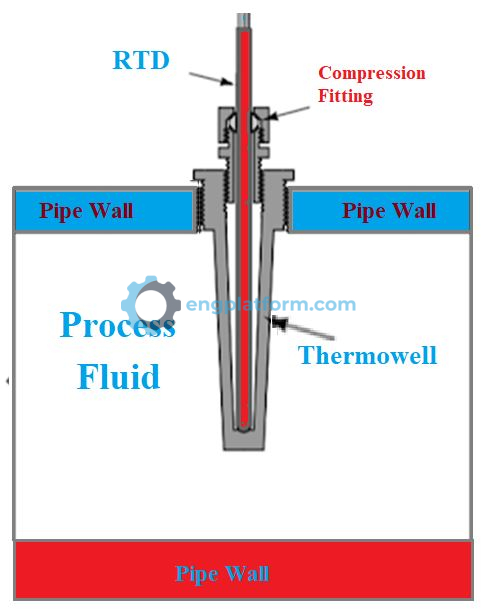

Thermowells are tubular fittings used to protect temperature sensors installed in industrial processes. The thermocouple sensor is inserted in the open end of the tube, which is located outside the process being monitored. The process fluid transfers heat to the thermowell wall, which in turn transfers heat to the sensor. If the sensor fails, it can be easily replaced without draining the vessel or piping.

Thermocouples use different types of metals based on the intended operating conditions, such as temperature range and working atmosphere. Different thermocouple types have distinct voltage output curves. When replacing a thermocouple, it is crucial to use the same type as the original. It is also necessary to use thermocouple or thermocouple extension wire of the proper type all the way from the sensing element to the measuring element. Large errors can develop if this practice is not followed.

RESISTANCE TEMPERATURE DETECTORS

Resistance temperature detectors (RTDs) are temperature sensors that use the change in electrical resistance of a metal with temperature to measure temperature. The electrical resistance of most metals increases as the temperature increases. This is known as the positive temperature coefficient (PTC) of metals. RTDs are very accurate and can be used to measure temperature in a wide range of applications. They are commonly used in industrial automation, medical devices, and other applications where precise temperature measurement is required.

RTDs are typically made of platinum, but other metals such as nickel and copper can also be used. Platinum is the most common material used in RTDs because it has a high melting point, good linearity, and excellent stability. RTDs are often encapsulated in probes for external temperature sensing and measurement. They can also be enclosed inside devices where they measure temperature as a part of the device’s function.

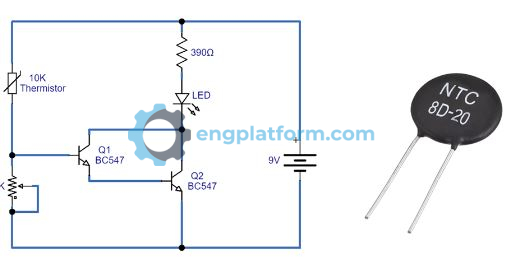

THERMISTORS

Thermistors are temperature sensors that use the change in electrical resistance of a semiconductor material with temperature to measure temperature. Thermistors can have either a negative temperature coefficient (NTC) or a positive temperature coefficient (PTC). NTC thermistors decrease in resistance as the temperature increases, while PTC thermistors increase in resistance as the temperature increases. Thermistors are more accurate than RTDs and thermocouples, but they have a much more limited temperature range. They also have a small sensing area and a low mass, which allows them to respond quickly to changes in temperature.

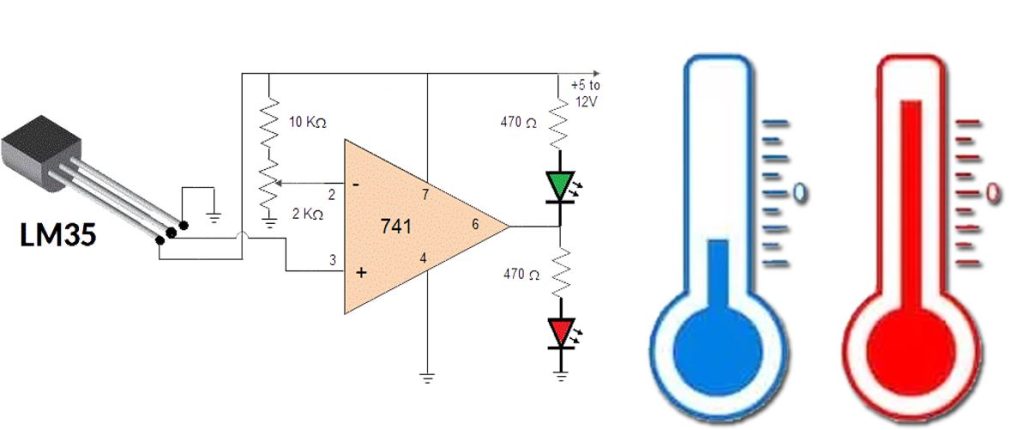

INTEGRATED CIRCUIT

Integrated circuit (IC) temperature sensors are small, accurate, and linear temperature sensors that use a silicon chip for the sensing element. They work by exploiting the temperature-sensitive voltage versus current characteristics of semiconductor diodes. IC temperature sensors are limited in temperature range (below 200°C), but they produce a very linear output over their operating range.

There are two main types of IC temperature sensors:

- Analog sensors: These sensors produce a voltage or current proportional to temperature.

- Digital sensors: These sensors convert the temperature data into a digital format of 1s and 0s.

Digital output temperature sensors are particularly useful when interfacing to a microcontroller, as they can be directly connected to the microcontroller’s digital input pins.